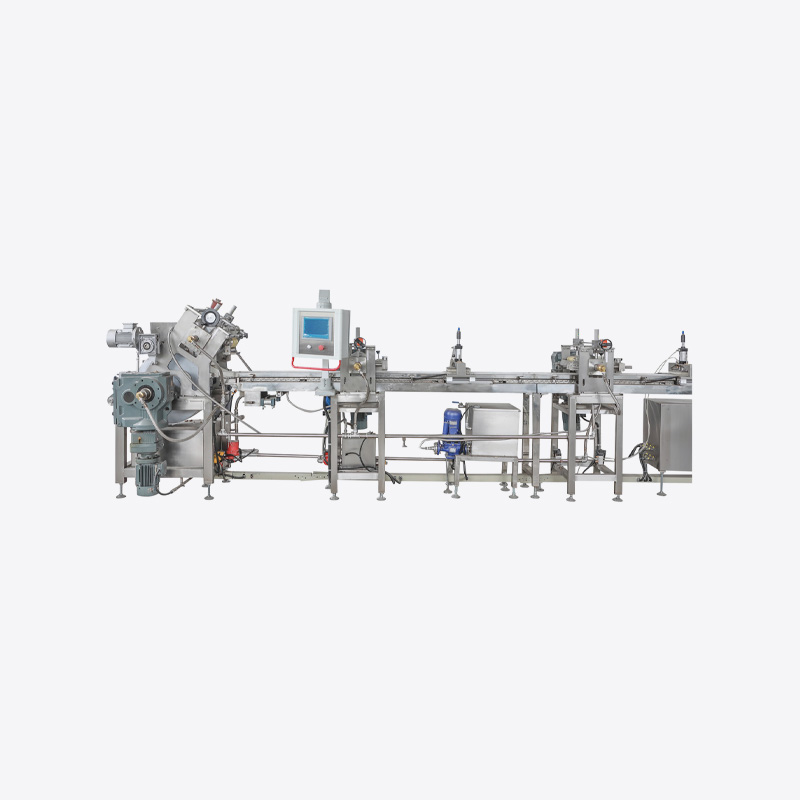

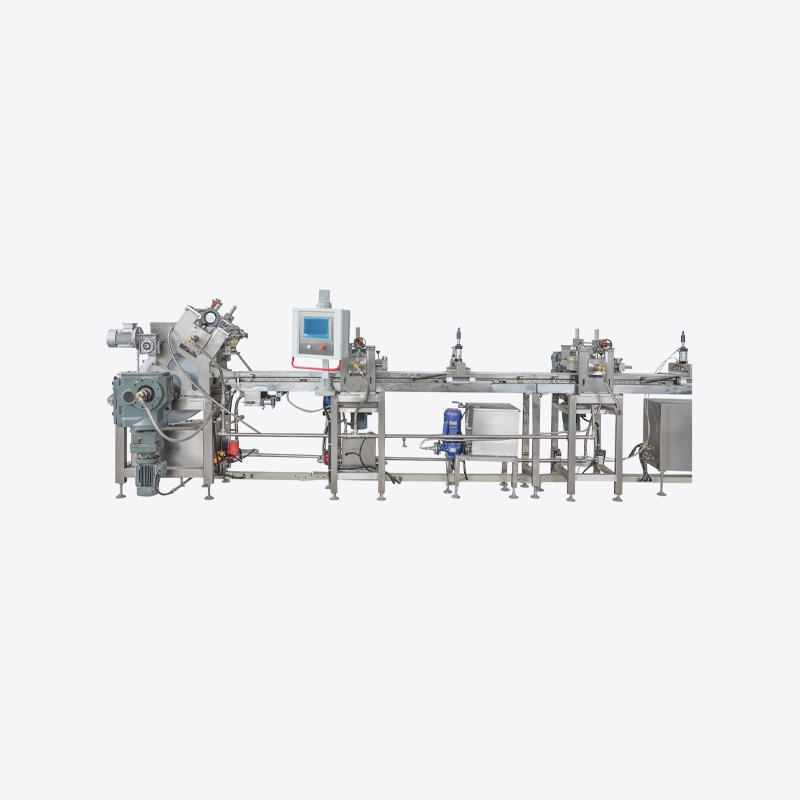

Introduction: Why Production Efficiency Matters in Chocolate Manufacturing

In an industry where flavor, texture, and speed determine competitiveness, production efficiency is the foundation of profitability for chocolate makers. A modern chocolate making machine transforms raw materials into finished products with higher repeatability and lower waste. This article examines concrete ways these machines improve production efficiency, offers practical implementation advice, and provides measurable metrics to track improvements.

How Chocolate Making Machines Streamline the Production Flow

Chocolate manufacturing is a multi-stage process: mixing, refining, conching, tempering, enrobing, and moulding. Dedicated machines that automate one or several of these stages reduce process variability and shorten cycle time. Automation eliminates manual handoffs between stations, reduces handling delays, and creates a continuous flow that scales better than batch-by-batch manual production.

Integrated process chains

Machines designed to integrate two or more steps — for example, a combined refiner-conche unit — remove idle time between stages. Integration reduces intermediate storage needs and the risk of contamination or inconsistent mixing that would otherwise require rework.

Fewer manual interventions

Automated dosing, temperature control, and timed mixing reduce the need for operator adjustments. When machines self-regulate critical parameters, cycle-to-cycle variation falls and operators can focus on supervision and quality control rather than repetitive manual tasks.

Quality Consistency: The Direct Efficiency Multiplier

Consistency drives yield: fewer off-spec batches means less trimming, recycling, or discarding. Chocolate making machines keep critical parameters — particle size, viscosity, and temperature — within tight tolerances that are hard to achieve by hand. The result is predictable quality and reduced time spent troubleshooting unexpected defects.

Precision control of process variables

Modern machines include precise RPM control, PID temperature loops, and in-line sensors. By monitoring and adjusting in real time, machines maintain the ideal particle refinement and fat dispersion levels, reducing the need for extended conching or corrective actions later in the line.

Reducing variation across shifts

With digital recipe control and saved process profiles, operators across different shifts can reliably reproduce the same product. This eliminates rework caused by human error and minimizes the learning curve for new staff, boosting effective production hours.

Labor Optimization and Cost Reduction

Labor is a major cost center in confectionery. Chocolate making machines reduce direct labor needs and shift human roles toward higher-value tasks such as quality assurance, maintenance, and product development. This change can lower hourly labor costs per kilogram of finished chocolate while preserving employment through upskilling.

Reduced manual handling and ergonomics

Automated conveying, dosing, and cleaning systems reduce repetitive lifting and exposure to heat, improving ergonomics and reducing injury-related downtime. Lower downtime and fewer sick days directly translate into more productive manufacturing hours.

Shift from routine tasks to supervision

When machines take over repetitive tasks, skilled staff can perform process optimization, preventive maintenance, and troubleshooting. This reallocation raises the average value of labor input and increases the speed at which problems are resolved — improving overall equipment effectiveness (OEE).

Throughput, Scalability, and Line Balancing

Throughput gains are a core advantage: machines typically operate longer and at steadier speeds than manual lines. They enable manufacturers to scale up output without linearly increasing labor or floor space. Proper line balancing between upstream and downstream machines prevents bottlenecks and maximizes throughput.

Designing for bottleneck elimination

Identify the slowest process step and choose machines that raise the capacity of that step. For instance, increasing conche speed or installing a higher-capacity tempering and moulding station will raise overall line throughput more effectively than upgrading non-limiting equipment.

Maintenance, Downtime Reduction, and Reliability

Well-designed chocolate making machines include features to minimize downtime: easy-access components, automatic lubrication, self-cleaning options, and predictive maintenance alerts. Lower downtime improves overall equipment effectiveness and reduces lost production hours.

Predictive maintenance and spare parts strategy

Sensors and PLC logs enable predictive maintenance — addressing wear before failure. Keep a lean inventory of critical spares and a preventive maintenance schedule tied to run-hours to reduce unplanned stoppages and keep uptime high.

Measuring Efficiency Gains: Metrics and KPIs

To quantify improvements after installing chocolate making machines, track specific KPIs: cycle time per batch, yield percentage, OEE, labor hours per ton, energy consumption per kilogram, and defect rate. These metrics make ROI calculations transparent and identify further improvement areas.

| KPI | Before | After (target) |

| Cycle time (min/kg) | 10–15 | 6–9 |

| Yield (%) | 92–95 | 96–98 |

| OEE (%) | 55–65 | 75–85 |

Implementation Checklist: From Selection to Ramp-Up

- Define throughput targets and product specifications before machine selection.

- Evaluate energy and footprint requirements to ensure fit with existing facilities.

- Request process trials or factory acceptance tests (FAT) with your actual recipe.

- Plan training for operators and maintenance teams three months before start-up.

- Implement KPI tracking from day one and iterate based on real data.

Conclusion: Real-World Impact and Next Steps

Chocolate making machines are not just capital expenses; they are strategic tools that improve throughput, consistency, and profitability. By reducing variation, lowering labor intensity, and enabling predictive maintenance, these machines raise effective production hours and product quality. When combined with a disciplined KPI program and operator training, the investment quickly converts into measurable gains. For manufacturers aiming to scale or enter premium markets, the right chocolate making machine is often the catalyst that transforms capability into competitive advantage.

English

English Español

Español