Achieving a perfectly thin and even chocolate coating is both an art and a science. With the right chocolate coating machine techniques, you can produce a smooth, glossy finish that enhances taste and appearance without creating an overly thick layer.

1. Choose the Right Type of Chocolate

Use couverture chocolate rather than compound chocolate if possible, as it contains a higher percentage of cocoa butter, which allows for a thinner, smoother coat.

Avoid overly viscous chocolate—chocolate with too much sugar or filler can be thick and harder to spread evenly.

Select the correct flavor intensity (milk, dark, or white) depending on the product you’re coating.

2. Properly Temper the Chocolate

Tempering is essential for controlling viscosity and ensuring a thin layer. Incorrectly tempered chocolate may thicken too fast or appear dull.

Follow the tempering curve:

Dark chocolate: Melt to 45–50 °C, cool to 27–28 °C, reheat to 31–32 °C.

Milk chocolate: Melt to 40–45 °C, cool to 26–27 °C, reheat to 29–30 °C.

White chocolate: Melt to 38–43 °C, cool to 25–26 °C, reheat to 28–29 °C.

Use a chocolate tempering machine or monitor temperature with a precise digital thermometer to avoid overheating.

3. Adjust Chocolate Viscosity

Viscosity is the key—the thinner the liquid chocolate, the thinner the coating.

Add cocoa butter (2–5%) to slightly thin the chocolate without changing the flavor.

Do not add water—even a drop will cause seizing and thickening.

Maintain working temperature so chocolate flows smoothly throughout the coating process.

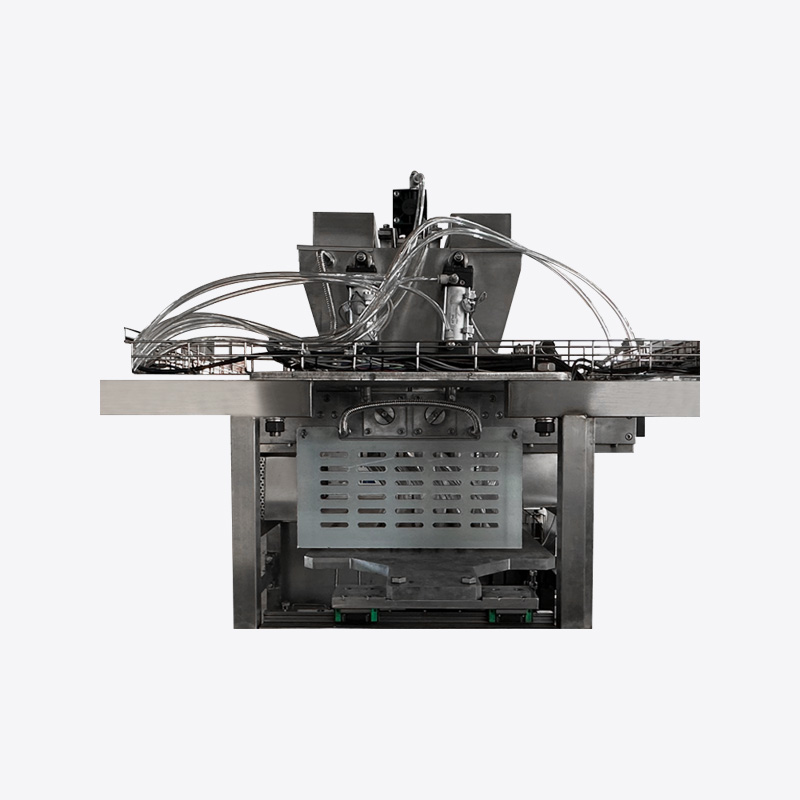

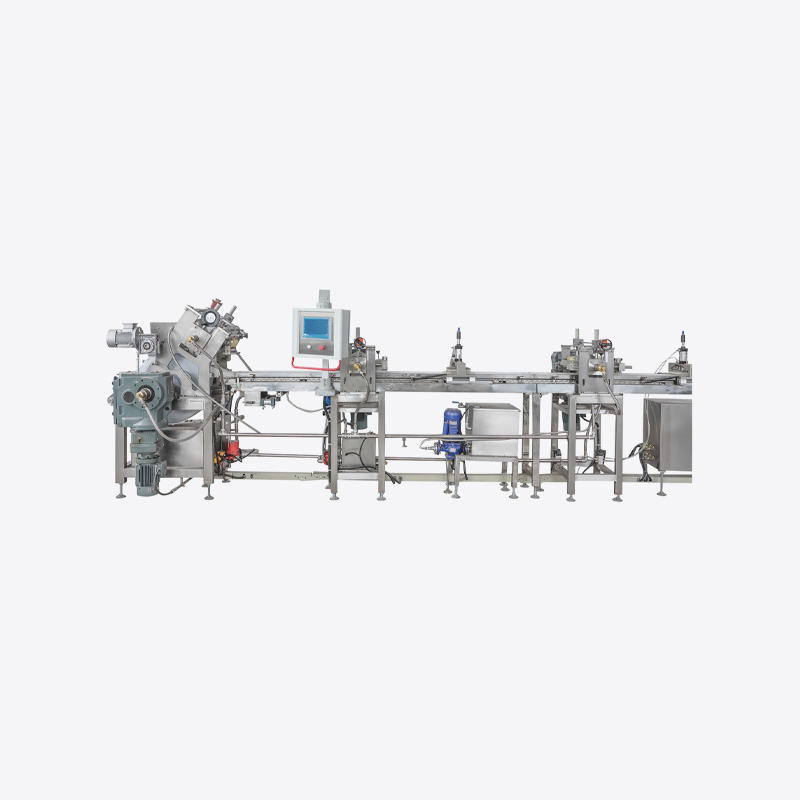

4. PreHeat the Coating Machine

Run the machine empty for a few minutes to bring it to working temperature before adding chocolate.

Ensure the enrobing curtain flows evenly—uneven flow will cause patchy thickness.

Check belt or drum temperature—a slightly warm surface helps the chocolate spread thinner.

5. Prepare the Items for Coating

Ensure the items are completely dry—moisture causes uneven chocolate distribution and sugar bloom.

Precool or slightly chill products to help the chocolate set quickly, reducing pooling at the bottom.

Arrange items evenly on the feed belt or in the coating drum so they do not touch or stick together.

6. Control the Flow of Chocolate

Adjust the curtain thickness—many machines allow you to regulate how much chocolate flows over the products.

Lower the pump speed slightly to reduce the volume of chocolate, resulting in a thinner coat.

Check the chocolate spreader or blower settings—these can help remove excess coating.

7. Use Air Blowers or Vibrators

Air blowers: Direct a controlled airflow over coated products to blow away excess chocolate while it’s still liquid.

Vibration plates or shaking belts: Light vibrations allow excess chocolate to drip off, creating a thinner final layer.

Adjust blower strength carefully—too much air can cause streaks or exposed spots.

8. Keep a Consistent Speed

Conveyor speed: A slightly faster belt speed reduces the time under the chocolate curtain, leading to a thinner layer.

Drum speed: For panning/coating drums, a higher rotation speed distributes chocolate more evenly and prevents thick buildup.

Avoid sudden speed changes—they can cause uneven coating thickness.

9. Cool the Coating Properly

Cooling tunnel temperature: Set to 8–12 °C for optimal setting without shocking the chocolate.

Gradual cooling helps prevent cracking or bloom while ensuring a smooth thin layer.

Avoid high humidity during cooling—condensation will ruin the coating finish.

10. Test and Adjust During Production

Run a few test pieces before starting full production.

Visually check for thickness—if the coating is too thick, increase airflow or reduce chocolate flow.

Weigh coated samples to ensure minimal weight gain from chocolate—this is a good quantitative check.

11. Maintain Clean Equipment

Clean enrobing belts, curtains, and blowers regularly to prevent buildup that can disrupt chocolate flow.

Filter the chocolate to remove crumbs or particles that increase viscosity.

Avoid contamination from old chocolate, which can thicken and affect coating quality.

12. Store Finished Products Correctly

Ideal storage temperature: 16–18 °C, with low humidity (below 50%).

Keep away from strong odors—chocolate absorbs smells easily.

Protect from light and heat to maintain coating appearance and texture.

13. Troubleshooting Tips for Thin Coatings

If coating is too thick: Increase blower airflow, add cocoa butter, slightly raise chocolate temperature, or speed up conveyor.

If coating is uneven: Check curtain flow, ensure product surfaces are smooth, and confirm chocolate is fully tempered.

If coating cracks: Reduce cooling speed and ensure the core product temperature is closer to the chocolate temperature before coating.

Key Takeaways

Thin chocolate coating depends on temperature control, viscosity adjustment, and precise machine settings.

Less is more—reducing chocolate flow and using blowers or vibration ensures a delicate layer.

Consistent monitoring during the process guarantees uniform, professionallooking results.

English

English Español

Español