The global energy bar market has witnessed tremendous growth over the past decade, driven by the increasing demand for convenient, on-the-go snacks that provide nutritional benefits. Energy bars are popular among athletes, fitness enthusiasts, busy professionals, and anyone seeking a quick and nutritious meal replacement.

Energy bars now come in an array of flavors, ingredients, and formulations designed to meet specific dietary needs, such as gluten-free, vegan, keto, or high-protein options. The increasing demand for high-quality, customized products has paved the way for a wide range of small-scale energy bar producers to enter the market. These smaller producers are often nimble, innovative, and able to cater to niche markets, which makes them a significant force in the energy bar landscape.

However, small-scale energy bar producers face unique challenges, particularly when it comes to scaling their operations without compromising on product quality or customer satisfaction. In this context, energy bar production lines play a crucial role in helping these producers expand their capacity efficiently while maintaining the flexibility to meet diverse consumer demands.

Importance of Small-Scale Production

In recent years, there has been a notable shift toward small-scale, artisanal production across various industries, and the energy bar sector is no exception. This trend reflects a growing consumer preference for locally sourced, customizable, and high-quality products. Small-scale energy bar manufacturers have the flexibility to experiment with a wide range of ingredients and cater to niche dietary needs such as gluten-free, vegan, low-carb, or high-protein options. These are often unmet by larger, mass-market producers, allowing small brands to establish a unique position in the market.

However, despite these advantages, small-scale energy bar producers face significant obstacles when it comes to scaling up. Many of these businesses struggle with limited financial resources, which can hinder their ability to invest in high-end production equipment. The ability to remain adaptable in production processes is crucial, as small-scale manufacturers often need to adjust quickly to shifts in consumer demand or trends, which can be challenging without the right infrastructure.

Furthermore, maintaining product consistency and quality is another ongoing challenge. As production volumes increase, so too does the pressure to ensure each batch meets the same high standards that customers expect. This becomes particularly difficult when production capacity expands without the necessary systems in place to manage it effectively. Without access to large-scale, automated manufacturing technologies, small-scale producers often find it challenging to compete with larger brands that can afford more advanced equipment, potentially putting them at a disadvantage in a rapidly evolving market.

What is Small-Scale Production?

Small-scale production in the energy bar industry typically refers to manufacturing operations that produce limited batch sizes, often tailored to specific customer segments or niche markets. These producers may focus on unique recipes, dietary needs, or local ingredients, offering consumers a personalized experience. Characteristics of small-scale production in this context include:

Limited Batch Sizes: Small-scale producers often operate with smaller production volumes, allowing them to be more agile and responsive to market trends.

Niche Markets: These producers cater to specific consumer needs, such as gluten-free, vegan, organic, or high-protein products, which may not be easily accessible through large commercial brands.

Flexibility: Small-scale production allows producers to quickly adapt to changes in consumer demand, whether it's launching a new flavor or switching ingredients to accommodate dietary trends.

While small-scale production offers several advantages, including innovation and the ability to cater to niche markets, it also presents challenges in maintaining production efficiency, ensuring consistent quality, and managing costs.

Role of Energy Bar Production Lines in Scaling Production

Energy bar production lines play a crucial role in enabling small-scale producers to grow their operations efficiently while maintaining product quality. These automated systems are designed to enhance production speed, improve consistency, and minimize human error. By integrating a production line, smaller manufacturers can streamline their processes, manage larger volumes, and meet increasing demand more effectively.

Automation for Precision: Automated production lines bring precision to each step of the manufacturing process, from mixing ingredients to shaping, baking, and packaging. This reduces variability between batches and ensures that every energy bar meets the same high standards. Automation minimizes the risk of human error, leading to more consistent product quality and better efficiency in the overall production process.

Increased Production Capacity: One of the most significant advantages of using a production line is the ability to scale output without needing to add significant labor or extend production time. With automated systems handling much of the work, small-scale producers can boost their production capacity, allowing them to fulfill larger orders and reach a broader customer base.

Lower Labor Costs: As production lines are automated, the need for manual labor decreases. This reduction in labor costs is especially important for small-scale manufacturers who may have limited resources. With fewer workers required for tasks such as mixing, packaging, and quality control, producers can allocate resources to other important areas of the business, like product innovation or marketing.

Flexibility and Scalability: Production lines offer remarkable flexibility, enabling producers to adjust production volumes based on fluctuating demand. Whether it's increasing batch sizes temporarily or experimenting with new formulations, a production line can adapt to meet these changes with minimal disruption. This scalability is essential for small-scale producers who want to expand without overhauling their entire operation.

What is Energy Bar Line?

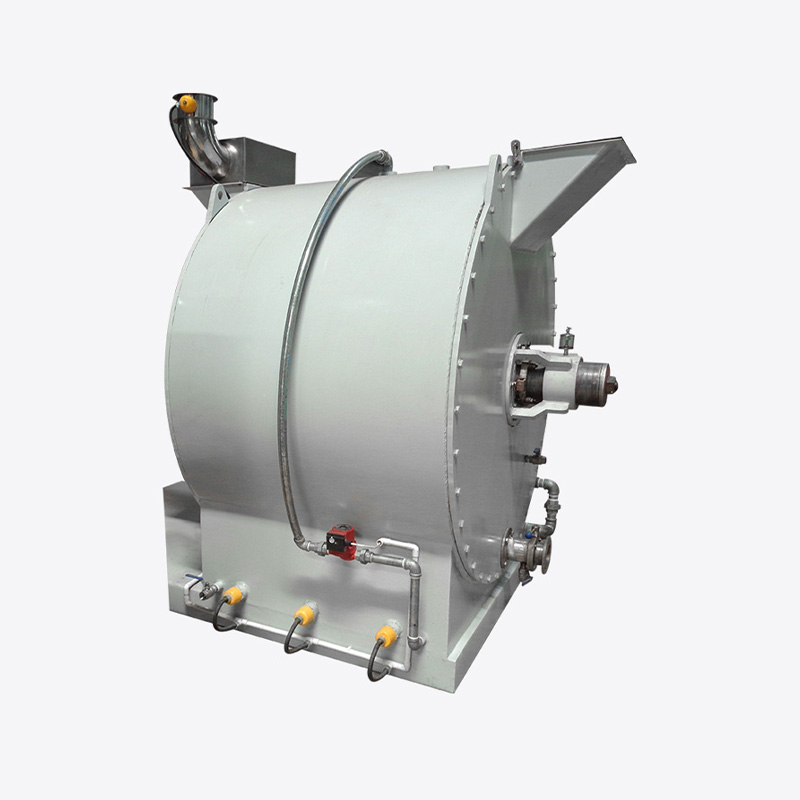

An Energy Bar Line refers to a set of interconnected production equipment and systems designed to manufacture energy bars efficiently and at scale. It typically includes machinery for mixing, shaping, baking (if needed), cooling, cutting, packaging, and labeling the energy bars.

Energy bar production lines can vary in complexity based on the level of automation and the scale of production. For smaller producers, a semi-automated or modular production line may be used, allowing flexibility for limited batch sizes and customization. Larger manufacturers, on the other hand, may use fully automated systems designed for high-volume production.

Key components of an energy bar production line typically include:

Mixing Equipment: Used to blend ingredients like oats, proteins, sweeteners, and flavorings into a uniform dough or batter.

Shaping and Molding Systems: These machines shape the dough into bars or other desired forms before moving to the next stages.

Baking or Cooling Chambers: If the energy bars require baking, ovens are used to cook them to the right texture. For non-baked bars, cooling chambers or refrigeration may be used.

Cutting and Portioning Machines: Once the bars have been formed and set, cutting equipment slices them into individual bars of uniform size.

Packaging Machines: These are responsible for wrapping or packaging the finished bars, often with additional labeling that includes nutritional information and branding.

Quality Control Systems: Sensors and automated checks ensure that the final product meets quality standards, such as size, texture, weight, and packaging.

Energy bar lines are essential for scaling up production while ensuring efficiency, consistency, and quality control. They allow manufacturers to meet growing consumer demand and produce large volumes of energy bars without compromising on product standards.

Technological Advancements in Energy Bar Production Lines

Recent advancements in production line technologies have greatly benefited small-scale energy bar manufacturers. These innovations provide enhanced efficiency, sustainability, and customization, helping small producers keep pace with larger competitors. Some key technological advancements include:

Smart Automation: The integration of AI and robotics in production lines has allowed for smarter automation, reducing downtime and improving real-time adjustments to the production process. For example, AI can analyze production data to predict maintenance needs, optimize ingredient mixing, and monitor quality control.

Energy Efficiency: Modern production lines are designed with energy-saving features that help reduce operational costs. These technologies allow small producers to minimize their energy consumption, leading to long-term savings and a smaller environmental footprint.

Advanced Packaging Solutions: Production lines now include automated packaging systems that improve both efficiency and accuracy. These systems can handle different packaging sizes, materials, and even customize labels based on consumer preferences or market trends.

Customization Flexibility: New production lines are highly flexible, allowing small-scale producers to change product formulations quickly. Whether it's altering the mix of ingredients or adjusting the cooking temperature, these production lines allow for rapid modifications to suit changing customer preferences.

The Benefits of Scaling Small-Batch Production with Energy Bar Lines

Integrating energy bar production lines into small-scale manufacturing operations offers multiple advantages, particularly for producers aiming to grow while maintaining product excellence. These production lines enable greater efficiency, cost savings, and flexibility, all while ensuring that quality is never compromised.

Improved Product Consistency: One of the standout benefits of automated production lines is their ability to ensure consistent ingredient mixing, uniform cooking, and standardized bar sizes. This results in energy bars that meet the same high quality with every batch, reducing variations that can occur in manual production methods. The precision of automated systems helps preserve the product's quality and appearance, which is critical for maintaining consumer trust.

Faster Production and Quicker Time-to-Market: Energy bar production lines significantly increase the speed at which bars are produced. With automation handling much of the work, producers can meet growing consumer demand without having to extend production hours or hire more workers. This boost in production efficiency not only increases output but also shortens the time it takes for products to reach the shelves, allowing small manufacturers to stay competitive in the fast-paced market.

Long-Term Cost Savings: While the initial cost of setting up a production line can be substantial, the long-term financial benefits make it a worthwhile investment. Energy bar production lines reduce labor costs by automating repetitive tasks, and they also help minimize waste and energy consumption. These efficiencies lead to lower operational costs, which contribute to greater profitability over time.

Adaptability to Market Fluctuations: Production lines offer flexibility that is vital for small-scale manufacturers who need to respond to shifting market demands. Whether scaling up production for a trending product or adjusting to seasonal changes, a flexible production line allows producers to quickly adjust production volumes without sacrificing quality or introducing bottlenecks. This adaptability ensures that small producers can keep pace with the ever-changing market without missing out on sales opportunities.

| Benefit | Description |

|---|---|

| Improved Product Consistency | Automated systems ensure consistent mixing of ingredients, uniform cooking times, and standard bar sizes, leading to consistent product quality across batches. |

| Faster Production and Quicker Time-to-Market | Energy bar production lines increase production speed, enabling producers to meet rising demand without extending working hours or hiring additional labor, reducing time-to-market. |

| Long-Term Cost Savings | Although the initial investment in production lines is high, long-term savings on labor, waste, and energy consumption make it a cost-effective solution. |

| Adaptability to Market Fluctuations | Flexible production lines allow small manufacturers to easily adjust production volumes, scale up for popular products, and respond to seasonal demand changes. |

Maintenance of Energy Bar Production Equipment

Routine Maintenance

Consistent, scheduled maintenance is crucial to ensure the efficient operation of Energy Bar Production Lines. This includes regular inspections, cleaning, lubrication, and fine-tuning of machinery. Each piece of equipment typically comes with a specific maintenance plan provided by the manufacturer.

Daily Tasks: Clean all surfaces, check for wear or damage, and lubricate any moving components.

Weekly Tasks: Inspect belts, hoses, and electrical components for signs of wear. Adjust the alignment and tension of belts and chains.

Monthly Tasks: Conduct more thorough checks, such as inspecting for rust, evaluating gears and bearings, and verifying that safety mechanisms are functioning.

Annual Tasks: Perform in-depth evaluations and replacements, including swapping out worn parts, updating software, and conducting precise calibrations.

Sanitation and Cleaning

Food safety and product quality rely on maintaining strict hygiene standards. Cleaning should be performed according to a fixed timetable to avoid contamination and ensure adherence to food safety protocols.

Daily Cleaning: Remove debris and residues from all surfaces and machine parts using food-safe cleaning products and thoroughly rinse all components.

Deep Cleaning: Conduct more thorough cleaning sessions periodically, including disassembling machinery if needed. After cleaning, ensure all parts are completely dried before reassembly to prevent microbial growth or mold.

Lubrication

Proper lubrication minimizes wear and tear, preventing damage to moving parts and extending equipment longevity. Always use lubricants specified by the equipment manufacturer and adhere to the recommended lubrication schedule.

Lubrication Points: Identify all necessary lubrication points, including bearings, gears, and chains.

Lubrication Frequency: Follow the manufacturer's schedule, which may vary depending on the machine's type and workload intensity.

Calibration and Fine-Tuning

Regular calibration is essential to ensure that all equipment functions correctly, maintaining the uniformity and quality of the energy bars produced.

Weight and Size Calibration: Regularly check and adjust the calibration of weighing and cutting machines to ensure that the bars meet specified weight and size standards.

Temperature Calibration: Confirm that the heating and cooling systems maintain the correct temperatures for optimal texture and shelf-life of the energy bars.

Energy bar production lines play a crucial role in helping small-scale producers scale their operations efficiently while maintaining the high-quality standards demanded by consumers. With the ability to automate processes, enhance flexibility, and improve cost efficiency, production lines are indispensable for small producers aiming to expand in a competitive market. Gusu Food Processing Machinery Suzhou Co., Ltd. stands at the forefront of providing cutting-edge energy bar production lines, offering solutions tailored to small-scale manufacturers. Their advanced machinery ensures that producers can optimize every step of the production process, from mixing and molding to packaging and labeling.

As technology continues to evolve, the future of small-scale production looks promising. Innovations in automation, artificial intelligence, and sustainability will continue to empower small energy bar producers, enabling them to meet growing consumer demand for personalized, high-quality products. For small-scale producers, partnering with experienced manufacturers like Gusu Food Processing Machinery Suzhou Co., Ltd. and investing in modern energy bar production lines is more than just a strategic decision—it's a long-term investment in growth, operational efficiency, and market success.

English

English Español

Español