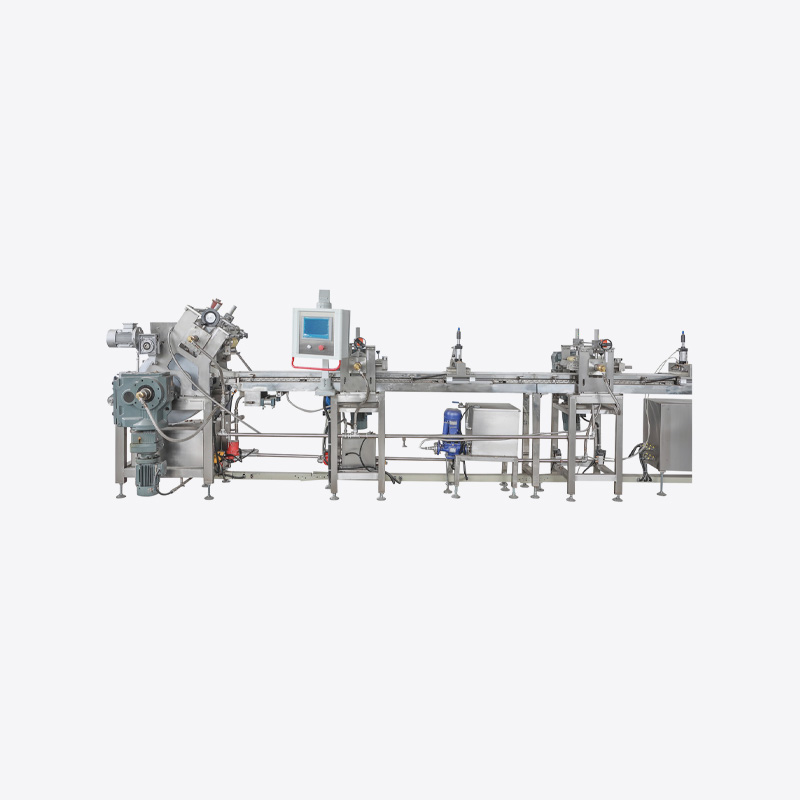

How a Chocolate Chips Machine Improves Consistency and Efficiency in Modern Production

Chocolate Chips Machine sit at the heart of many confectionery and bakery operations, turning recipes into uniform pieces that behave predictably in baking, coating and packing. When a line can deposit and size chips uniformly, the rest of the process—cooling, demolding, packing—runs with fewer surprises. Manufacturers who pay attention to the small mechanics of chip forming save time, reduce waste and deliver a steadier product to customers.

Why uniform chips matter more than you might think

On the face of it, chip size seems cosmetic: a cookie looks nicer when chips are consistent. But the practical effects run deeper.

- Baking behavior. Even small differences in chip volume change melt rate and distribution. A batch of cookies with variable chips can show inconsistent texture and oven time.

- Packaging and weight control. Chips that vary in size lead to weight variance across packs, causing more rejects in automated packaging lines or inaccurate net weights.

- Consumer experience. Texture and flavor release are affected by how a chip melts and interacts with the other ingredients.

- Downstream equipment load. If chips are inconsistent, cooling tunnels and demolders must deal with unpredictable parts; that raises the chance of jams or rework.

So a single dependable deposit at the start means fewer problems later. That's why the forming stage gets so much attention on efficient lines.

The main causes of size and shape variation

A lot of producers blame the machine first, but variation usually springs from a mix of process and environment. Here are the usual suspects:

- Temperature drift. Chocolate viscosity moves with temperature. If the supply temperature wanders, deposit volume and edge definition change.

- Feed inconsistency. Entrained air, variable hopper fill levels, or uneven feeding RPMs produce different deposit pulses.

- Worn or misaligned tooling. Nozzles and dies wear over long runs; seals and valves can develop small leaks that change metering.

- Operator setup changes. Different operators may set nozzle heights, conveyor speed or cycle timing slightly differently.

- Ambient conditions. Humidity and shop temperature affect cooling rates and surface finish, especially with tempered chocolates.

Addressing these is mostly practical: good thermal control, predictable feeding, routine inspection, and standardized startup routines.

How modern equipment adapts to different chocolates and recipes

Chocolates vary: couverture, milk, compound, and mixes with inclusions like nuts or crisped rice. They require different handling. Useful machine features that allow one line to run multiple recipes include:

- Adjustable head geometry. Interchangeable nozzles and modular heads let you switch deposit shape and spacing without a complete teardown.

- Programmable deposition profiles. The ability to program multi-shot sequences and dwell times is invaluable for filled products or two-layer pieces.

- Fine thermal control. Stable, zoned heaters (and sometimes active cooling) keep chocolate within a narrow working band as it moves from hopper to nozzle.

- Variable metering. Pumps or gear meters that can alter stroke or speed let you hit different portion weights reliably.

If your line needs to make a variety of chips—large, small, hollow, filled—the upfront investment in flexible equipment pays off in fewer changeover headaches.

Common production problems and how to reduce them

Below are common practical problems that slow lines and what you can do to reduce each one.

Irregular shapes or stray strings

- Why it happens: Poor anti-drip control, worn nozzles, or sudden temperature drop.

- Fixes: Fit anti-drip valves, swap nozzles before they reach tolerance, keep a short pre-run stabilizing period.

Nozzle blockages and buildup

- Why it happens: Chocolate cools in the orifices between runs or when small particles lodge.

- Fixes: Short, scheduled purge cycles; use strainers in the hopper to catch debris; design quick-release nozzle housings.

Fluctuating output during long runs

- Why it happens: Feed pump slip, small air entrainment, or thermal drift.

- Fixes: Monitor feed pressure and add a simple pressure buffer; use gentle degassing practices when handling fresh melt.

Excess startup waste

- Why it happens: Initial cycles before process stabilization produce off-spec pieces.

- Fixes: Implement a two-bin startup routine (startup output goes to rework), or use a short inline recirculation loop.

Frequent manual interventions

- Why it happens: Poorly designed cleaning or long changeover times.

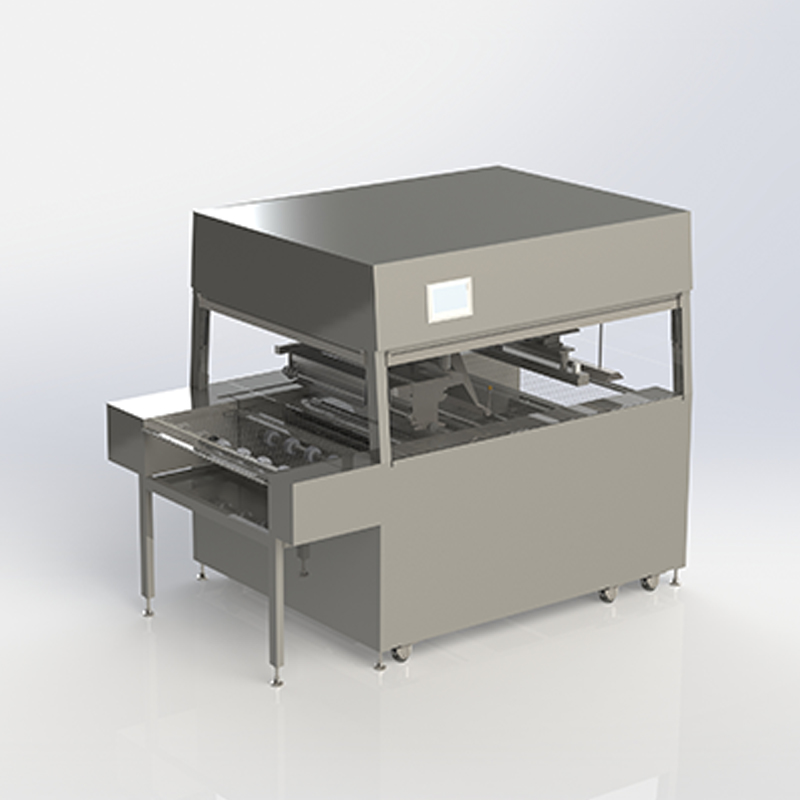

- Fixes: Choose machines with tool-less disassembly for daily cleaning and invest in a spare head assembly to hot-swap between runs.

Many of these fixes don't take heavy capital—just consistent habits and small kit upgrades that pay back quickly.

Practical operator practices that make a big difference

Good machines help—skilled crews make them sing. Below are operator habits that consistently improve outcomes.

- Pre-shift checklist. Ten items that take three minutes: hopper cleanliness, nozzle fit, conveyor alignment, feed pressure, basic thermal setpoints, spare parts present.

- Short warm-up and balancing run. Run a 1–3 minute balancing cycle to let temperatures and flow stabilize before putting product on the main conveyor.

- Two-stage startup. Route first batch to a rework container and start full production only once weight and shape sampling are in range.

- Recorded shift notes. A quick log of charge time, ambient temp, and any warnings helps maintenance spot trends before they escalate.

- Smooth handling technique. Avoid abrupt starts and stops with hand-held loaders and attachments—smoother handling reduces mechanical stress and keeps deposits consistent.

Train all shifts the same way, and variance from operator to operator drops fast.

A simple daily and weekly maintenance routine

Maintenance doesn't have to be onerous; make it routine and you'll avoid most surprises.

Daily (5–15 minutes):

- Visual check of nozzles, seals and feed lines.

- Quick sample run: take 20 deposits, weigh three, confirm tolerance.

- Wipe clean accessible surfaces and check hopper screens.

- Note any alarms or odd noises in the shift log.

Weekly (30–60 minutes):

- Remove and deep clean deposit head(s).

- Inspect nozzle orifice wear; replace if out of tolerance.

- Check pump couplings, valve seals and connections.

- Verify thermal sensors and confirm setpoint drift < specified tolerance.

Monthly / Quarterly:

- Swap spare parts and update spares inventory.

- Firmware/PLC review and backup of recipes.

- Operator refresher training and review of production KPIs.

- A little attention on schedule keeps the line predictable.

- Measuring success: key metrics you should track

Pick a handful of easy KPIs and review them weekly. That keeps the conversation fact-based.

- Deposit weight variance: % out of tolerance per shift.

- Startup scrap ratio: weight or value of scrap during changeovers.

- Mean time between nozzle maintenance: how many runs you get before replacing nozzles.

- Unplanned downtime minutes per month: minutes lost vs. scheduled production time.

- Changeover time: average time to switch SKUs.

If you start small—one or two metrics—and improve them, the rest of the line usually benefits.

Case snapshots — practical examples from the floor

Here are plausible, concise examples to illustrate how process changes help.

Case 1 — Small bakery, big range:

A regional bakery made eight cookie SKUs on one line. They adopted modular heads and recipe storage. Changeover time fell from 75 minutes to 28 minutes; startup scrap dropped by 40% because operators selected the saved recipe matching ambient conditions.

Case 2 — Specialty confectioner:

A candy maker struggled with nozzle blockages during rainy seasons. Adding simple hopper covers and a short inline heater before the feeder stabilized flow and cut blockages by two-thirds.

Those sorts of small, targeted fixes are where most payback lives.

Choosing a machine that won't become a bottleneck

When evaluating new depositors, think about real production, not the spec sheet buzzwords. Ask vendor reps for run demos with a recipe similar to yours. Consider:

- Flexibility: Can the head handle your target shapes and viscosities with minimal tool changes?

- Serviceability: How quickly can a head be swapped, and are spare heads available?

- Thermal control: Can the machine hold temperature within the narrow band your chocolate needs?

- Integration: Does the control system offer simple recipe storage and PLC communication for line synchronization?

- Spare parts and local support: How fast can parts be shipped and field techs be dispatched?

A good purchase decision balances current needs and future options. Sometimes a slightly more modular unit saves far more in downtime and changeover time than the price difference at purchase.

Designing changeovers to be predictable

Changeovers are an inevitable source of lost time. Here are design and process ideas to make them shorter and less risky:

- Recipe banks: Store recipes keyed to actual shop conditions. Include ambient temp and basic adjustments.

- Quick-release toolings: Use heads and nozzles that can be removed and installed with minimal tools.

- Prepped spares: Keep a cleaned, assembled spare head that can be swapped in while the other is cleaned off-line.

- Changeover checklist: A two-page checklist that lines up physical steps with control system recipe loads reduces mistakes.

Treat changeovers like an engineered process; do not improvise.

Scaling up: what changes when volume grows

When production grows, stress points change. You'll encounter:

- More frequent refill cycles. Consider larger hoppers or automated refill systems.

- Greater wear on orifices and seals. Plan for higher part turnover and reorder cycles.

- Need for better data. Volume favors simple, robust process monitoring—set alerts when weight variance creeps.

- Logistics for spares and service. A small downtime at high volume costs more; prioritize local parts and rapid service contracts.

If you plan growth, factor these operational realities into the buying decision.

Final practical checklist before committing

Use this quick checklist with procurement or the line team before buying or upgrading a depositor:

- Can the machine replicate your most common deposit shape with the material you use?

- How long to swap a head or nozzle in practice?

- Does the control store multiple recipes and export logs?

- Are spare heads available and affordable?

- How is local service and what is the typical response time?

- What are consumable replacement intervals (nozzles, seals)?

- Does the seller allow a short trial run with your materials?

If most of these check boxes are reasonable, you're looking at equipment that will support long-term, steady production.

On a production line, consistency compounds into reliability. That single reliable deposit earlier in the chain keeps ovens on schedule, reduces rejects, simplifies packaging, and keeps customers happy. The practical levers are straightforward: stable temperature and feed control, clean and inspected tooling, sensible operator routines, and machines chosen for flexibility and maintainability.

A modest investment in the right forming equipment—and a few process habits—often returns quickly in reduced waste and smoother days on the floor. If you want, I can turn this into a printable one-page checklist and a quick changeover SOP that your operators can pin next to the machine.

English

English Español

Español