How Chocolate Depositor Technology Supports Modern Confectionery Production

Why depositing matters right now

The chocolate aisle today looks nothing like it did ten years ago. Brands keep adding fillings, textures, and shapes that were once niche. That change is more than marketing: it forces production teams to rethink how product is made from the very first step — depositing chocolate into a mold or onto a conveyor. A reliable Chocolate Depositor is the machine that turns recipes and designs into repeatable realities on the factory floor.

Put simply: good depositing saves time later. Poorly deposited chocolate creates problems at cooling, demolding, and packaging. Those small problems pile up into real cost and schedule headaches. So, when a factory manager evaluates equipment, the depositor is often the linchpin for both daily throughput and future product plans.

What a depositor actually does

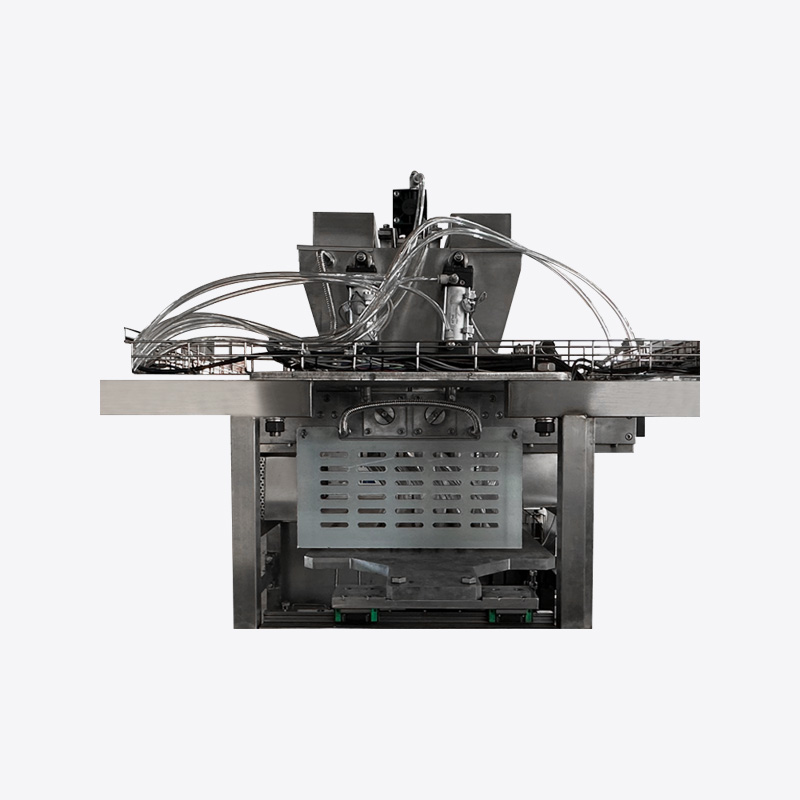

Think of a depositor as a precision dispenser for chocolate. It controls how much chocolate goes into each cavity, where it lands, and when. For one product it might lay down a shell; for another it might deposit a thin ribbon between layers. The important parts are flow control, timing, and repeatability.

Key depositor actions in production:

- Metering exact volumes so products match weight tolerances.

- Timing deposits to avoid mixing of adjacent layers.

- Positioning chocolate consistently so molds fill correctly.

- Handling different viscosities without manual rework.

If these four things work reliably, the rest of the line — cooling tunnels, demolders, packers — can keep a steady pace.

Shapes and molds: why they change the game

Different product shapes are not just visual choices; they change how chocolate must flow. A deep, narrow cavity needs a different depositing strategy than a wide shallow mold. Hollow shells behave differently from filled pralines. When a depositor can switch patterns and head layouts quickly, a mixer of product types becomes much easier to run.

Practical implications:

- Hollow shells need controlled pulses so walls form evenly.

- Filled products need an initial shell, a fill, then a seal — timing matters.

- Layered snacks need precise placement so textures don't merge.

Factories that frequently run varied SKUs benefit from depositors with modular heads or programmable deposit sequences. That reduces physically swapping parts and cuts the setup time between runs.

Portion control: more than just weight

Portion control affects packaging, costs, and customer expectation. If each piece is off by a gram, the packaging weight adds up and so does ingredient cost. Tighter tolerances also mean fewer rejected packs at the end of the line.

How depositors help:

- Consistent cycle volumes lower the need for manual weighing.

- Stable deposits reduce downstream waste and rework.

- Predictable output makes scheduling easier; QA checks become more straightforward.

A practical tip: use statistical sampling at shift start and every changeover. Record deposit volumes for 30 cycles, calculate the mean and standard deviation, and use that to confirm the depositor is "in spec" before the run. That small step catches drift early.

What matters for small and medium factories

Large plants can justify complex automation. Smaller factories need machines that match their staffing and space constraints.

Operators at smaller sites often say they want:

- Simple controls that anyone can learn quickly.

- Fast, tool-free cleaning for daily washdowns.

- Compact footprint for limited floor space.

- Flexibility to switch recipes without deep technical support.

A depositor with a clear human-machine interface (HMI) and pre-set recipes helps reduce training time. And accessible parts — panels that open without tools, easily removable nozzles — speed cleaning and lower the chance of downtime.

Checklist for SMEs:

- Can the head be removed in under five minutes?

- Is the control panel intuitive for someone on their first week?

- Are common spare parts easily available locally?

Design decisions that reduce material waste

Waste happens during changeovers, start-up, and in dead zones where chocolate sits and begins to cool. Depositors can help lower waste through both mechanical and process design.

Design choices that reduce waste:

- Smooth internal surfaces that let chocolate flow out cleanly.

- Short, direct pathways from hopper to nozzle to avoid hold-up.

- Controlled ramp-up and ramp-down so deposits don't overshoot at cycle start/stop.

- Anti-drip mechanisms and synchronized valves to prevent stray drops.

On the process side: plan short purge cycles and collect startup output into rework containers rather than letting it go to scrap. Many factories reuse validated startup material in non-premium lines, cutting losses.

Flexibility: how equipment enables new products

When a team wants to trial a new item — say, a filled bar with a crunchy core — the depositor is often where the plan succeeds or fails. Machines that can be reprogrammed for different deposit shapes and volumes let R&D move faster, and allow production to test limited runs without heavy investment.

Examples of flexibility:

- Multi-nozzle heads for different deposit patterns in one pass.

- Software that stores many recipes to switch between at the touch of a screen.

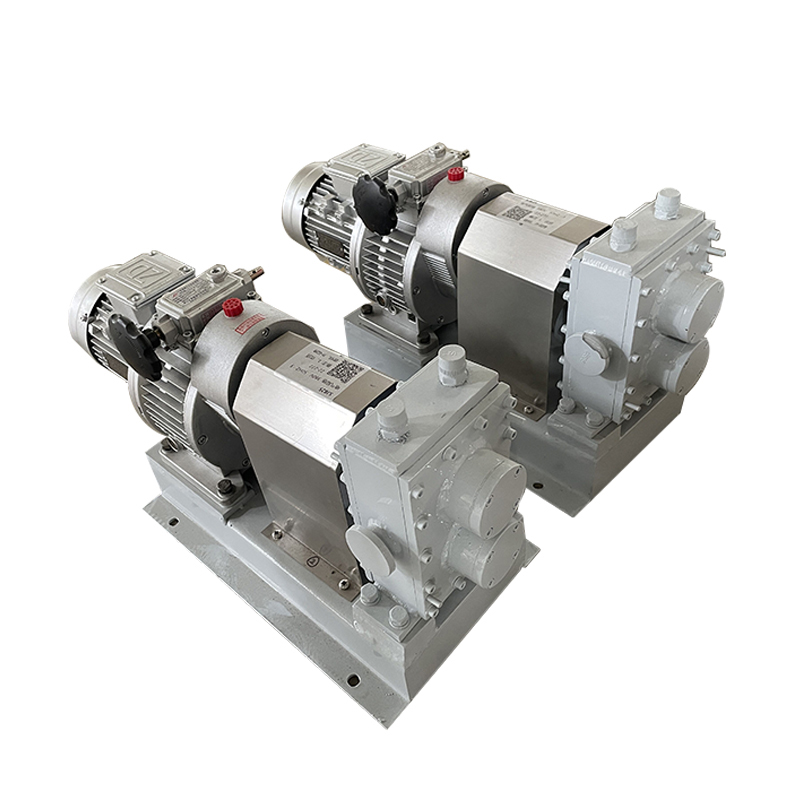

- Thermal control available to adjust viscosity for different chocolates.

A practical workflow: prototype the deposit sequence offline with small test molds, then save the recipe. When ready to scale, the saved recipe becomes a reproducible starting point for production, reducing trial-and-error on the line.

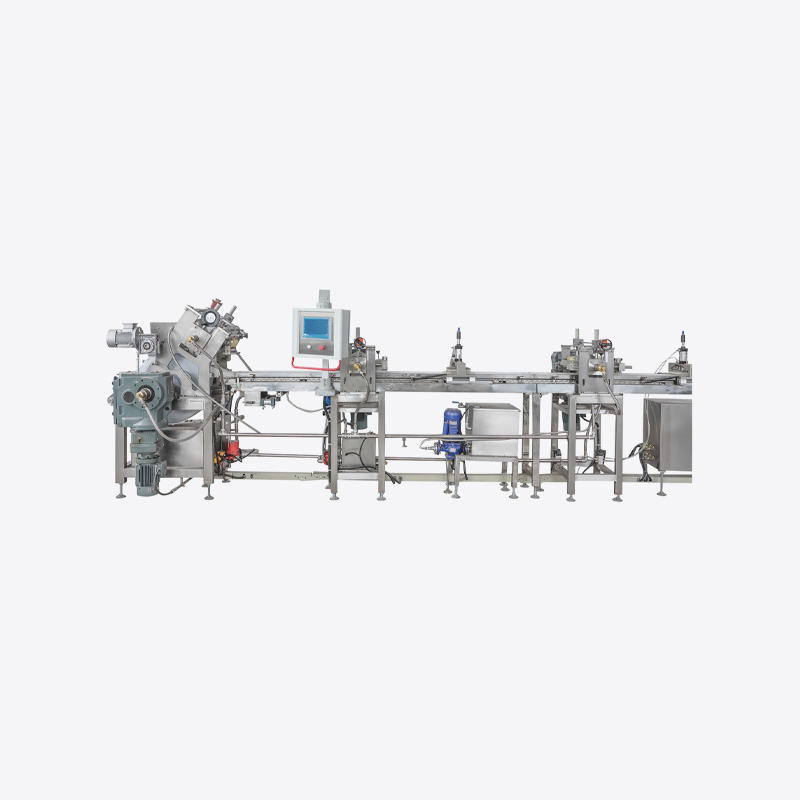

Integration: the depositor as a line player, not a solo act

Depositers do their best work when they are synced to upstream and downstream stages. A mismatch in timing between depositor and cooler leads to backups; too fast a depositor and the next station can't keep up.

Key integration points:

- Synchronize depositor cycle with conveyor index timing.

- Match deposit speed to cooling tunnel capacity to avoid jams.

- Ensure control systems talk: modern depositors can exchange signals with PLCs for coordinated line stops and start sequences.

Integration also involves data: simple monitoring of deposit volumes and cycle times helps planners spot trends. If deposits slowly creep higher over weeks, that's an indicator of a maintenance need or wear in metering components.

What good maintenance looks like

Maintenance is where theory meets reality. Machines that are easy to clean and inspect are easier to keep running. A short daily routine prevents most surprises.

Daily checklist (five minutes):

- Check hopper levels and screen for debris.

- Visual check of nozzle seals and fasteners.

- Quick run of 20 cycles and measure a sample deposit.

- Wipe accessible surfaces and ensure cooling vents clear.

- Log any unusual sounds or behavior.

Weekly tasks:

- Remove deposit head and clean thoroughly.

- Inspect wear parts such as seals and rotary components.

- Check calibration against a known weight standard.

Monthly tasks:

- Review spare parts usage and reorder what's low.

- Test electrical connectors and check software updates.

- Run a short training refresher with operators.

A culture where operators note small issues early — a tighter seal here, an odd noise there — prevents those items from turning into production-stopping faults.

Practical tips from operators

Here are some practical habits that experienced operators use; they're cheap to adopt and often make a real difference:

- Warm-up routine: set a short pre-run warm interval so chocolate hits target viscosity before starting the first deposit. That reduces early-run rejects.

- Two-bin startup: collect the first few deposits into a rework bin rather than running them through cooling and packing.

- Recipe snapshots: save multiple versions of recipes labeled with batch conditions (ambient temp, chocolate type) so teams can pick the correct one quickly.

- Visual templates: place a laminated template at the station showing nozzle positions and replacement part numbers — handy for quick swaps.

- Fast swap spares: keep a "ready-to-go" head assembly cleaned and standing by; swapping the whole head can be faster than trying to fix one mid-run.

These practices don't require high investment; they require consistency.

Selecting a depositor with future-proofing in mind

When making a purchasing decision, think beyond the immediate spec sheet. Consider how the machine will fit into growth plans and product roadmaps.

Questions to ask suppliers:

- Can this machine accept additional deposit heads or modules later?

- Are spare parts standardized across other models?

- Is software updated regularly and is it backward compatible?

- How easy is it to get technical support and documentation?

A machine that is modular — one that allows adding capacity or features with minimal downtime — offers better long-term value than a "fixed" unit priced slightly lower up front.

Case scenarios

Scenario A — Regional bakery expanding SKUs

A regional bakery wanted to add a filled chocolate snack line. They chose a depositor with programmable multi-shot heads. Result: setup time dropped from 90 minutes to 25 minutes, and early runs matched target weights within three cycles.

Scenario B — Small specialty maker reducing waste

A boutique chocolatier struggled with startup scrap. Implementing a two-bin startup and an anti-drip nozzle cut first-batch scrap by half. The saved chocolate paid for the nozzle upgrade in under three months.

These are plausible, real-world outcomes that many small-to-mid shops report when they pair sensible process changes with the right equipment.

Measuring success: metrics to watch

To evaluate whether a depositor is doing its job, track a few simple KPIs:

- Percentage of deposits within weight tolerance.

- Average setup time per SKU changeover.

- Scrap rate during startup and changeover.

- Unplanned downtime attributed to depositor faults.

Tracking these over months turns subjective impressions into actionable data, showing whether investments in equipment or training are paying off.

Final practical checklist before buying or upgrading

Here is a condensed checklist you can use when assessing options or preparing a business case:

Technical fit:

- Can it handle your typical mold shapes and viscosities?

- Is it programmable for multi-shot or multi-layer deposits?

Operational fit:

- How long does a changeover take in practice?

- Is daily cleaning simple and tool-free?

- Maintenance & support:

- Are spare parts available quickly?

- Is local technical support accessible?

Future fit:

- Can the model be expanded or upgraded?

- Does the vendor provide firmware and recipe migration?

Cost & ROI:

- Estimate setup time saved per month.

- Project scrap reduction and its monthly value.

- Factor in training time and spare parts costs.

A clear checklist speeds decision-making and helps get buy-in from production and procurement teams.

Chocolate depositors are often underappreciated until they are needed. When they work well, whole production lines flow with fewer interruptions, and teams can focus on product quality rather than firefighting. When they don't, everything downstream feels the impact — from cooling tunnels to packing stations.

Selecting the right depositor is both a technical and a practical decision. Choose the machine that fits your current process, but also the one that gives you options for tomorrow. With modest process discipline — a short startup routine, a clear maintenance schedule, and a few operator habits — the difference on a production day can be striking: fewer stops, fewer rejects, and steadier output.

English

English Español

Español