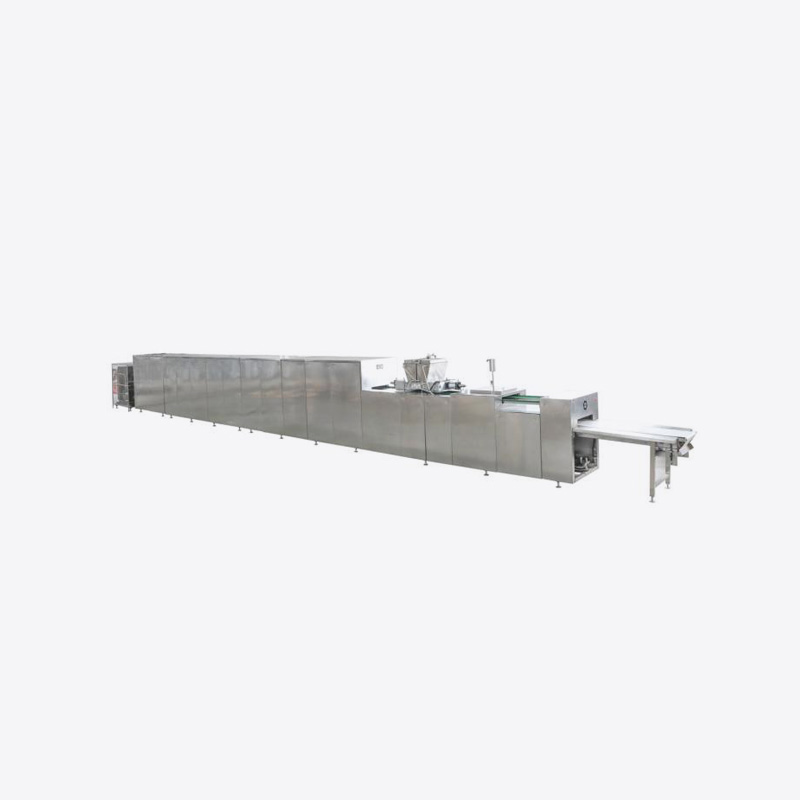

How to Choose a Chocolate Depositor Manufacturer

Chocolate Depositor Manufacturer — choosing the right one matters more than many teams realize. The depositor sits where recipe, temperature control, and line logistics meet; it determines portion accuracy, affects yield, and frames how flexible your line can be for new products. Buy the wrong machine, and you may spend months wrestling with cleaning, rework and inconsistent portions. Buy wisely, and the depositor becomes one of the reasons your launch runs hit targets and your margins hold steady.

Why the depositor decision matters

A depositor is not just a nozzle on a conveyor. It is the control point for portion mass, the interface between tempered chocolate or filling and the package, and often the pacing element for packaging steps downstream. Its design and the supplier's capabilities determine:

- How consistent portion weight and geometry will be across a long run.

- How much time and labor are needed for changeovers and cleaning.

- Whether you can scale SKUs quickly or you're stuck hand-trimming special runs.

- How easy it is to integrate the machine into your line control and traceability systems.

Two quick examples make the point. In one mid-sized plant, replacing a manual dropper with a portion-control depositor cut giveaway by several percent and eliminated a daily trimming task. In another case, a bakery bought a low-cost unit that looked fine on demo but required full disassembly and four hours of cleaning between flavors, turning what should have been a short shift into a long, costly clean-down. The right choice avoids those pitfalls.

Core depositor features that matter in real production

When you evaluate machines, focus on features that touch day-to-day operations—not just spec sheet buzzwords.

Portion control and metering method

Portion accuracy saves money. Machines that meter by weight or use closed-loop feedback are preferable where margin is tight; timed-valve approaches are simpler and cheaper but drift with viscosity changes. Ask for repeatability data: the supplier should show standard deviation on portion weights across a test run using your product or a close proxy.

Temperature management from hopper to nozzle

Chocolate and many fillings have narrow workable temperature ranges. The depositor should maintain temperature uniformity, avoid local hotspots and support recipe setpoints. Key design elements: jacketed hoppers, heated transfer lines, accurate sensors, and alarms that trigger if zones drift. For creams and fillings, gentle, even heating is often preferable to aggressive local heating that can separate fats.

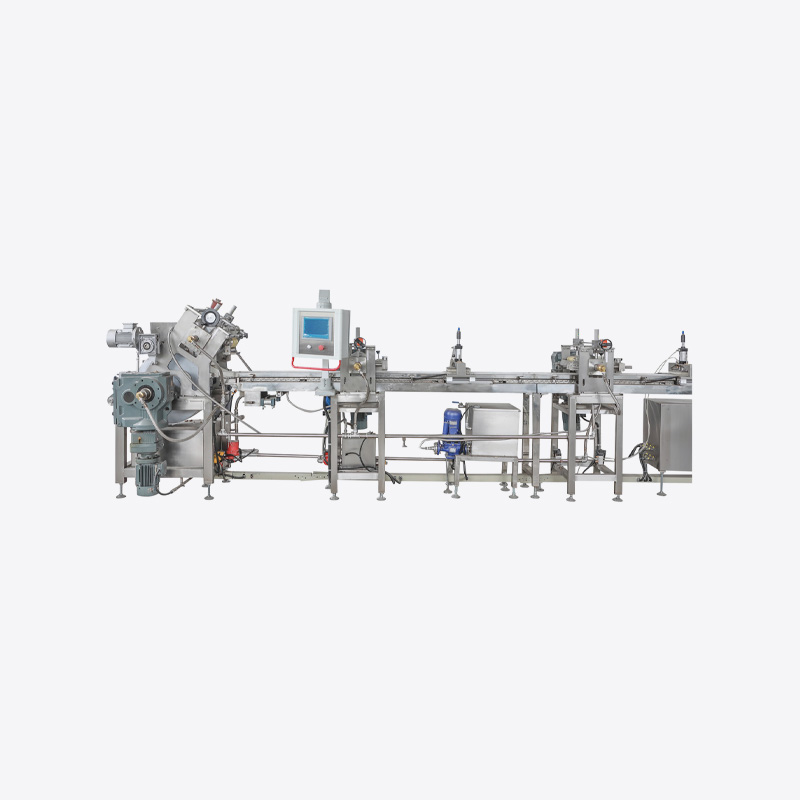

Pump and drive technology

Piston, gear and servo-driven pumps are common. Piston and gear pumps handle higher viscosity masses well; servo systems give fine control for quick response to recipe changes. Peristaltic pumps can simplify cleaning in some layouts because the product contacts the hose only, but check that they match your throughput and viscosity needs.

Nozzle and head flexibility

The nozzle family defines shapes and fills you can deliver. Quick-change nozzle modules, modular manifolds and adjustable plungers make it practical to switch SKUs. Inspect how nozzle swaps are performed: tool-free or requiring extensive instrumentation changes? Time a real nozzle swap during demo.

Recipe management and HMI usability

An operator-friendly HMI with clear recipe storage shortens learning curves and reduces mistakes. Look for recipe locking, exportable logs, and easy recipe recall. If you plan audits or traceability, ensure the system logs recipe IDs, batch numbers and run timestamps.

Cleanability and hygienic design

The more easily a machine is cleaned, the less downtime you'll have. CIP capability is ideal when available. Otherwise, look for tool-free disassembly, minimal dead zones, hygienic welds and smooth surfaces. In allergen-sensitive environments, validated cleaning procedures and quick-change gaskets are essential.

Integration and communications

If the depositor must talk to checkweighers, vision systems or MES software, confirm supported protocols (Ethernet/IP, Modbus, OPC-UA). A machine with standard communications avoids expensive integration work and supports line-level traceability.

Spare parts and maintainability

Ask for an inventory of wear parts, expected life hours, and lead times. Machines that use common, non-proprietary consumables are easier to maintain. A local distributor or service partner speeds repairs.

How a depositor improves throughput, reduces waste, and supports new SKUs

The practical benefits of the right machine are both immediate and cumulative.

Faster, more consistent portioning

Automated portioning replaces hand-filling and trimming, increasing units per hour without adding labor. It also improves portion consistency, stabilizing final package weight and reducing giveaway.

Lower rework and better yield

Accurate deposits limit the need for downstream trimming or rejects. That reduces material waste and labor tied to rework.

Faster product introduction and smaller batch economics

If changeovers are fast and cleaning is short, you can run shorter production lots economically. That supports seasonal SKUs, limited editions, and market tests without eating large chunks of plant time.

Integrated quality controls

A depositor that feeds data to in-line inspection and checkweighing makes catching defects automatic. Reject logic and trace logging save recall headaches later.

Which depositor options are suitable for small businesses vs larger operations

Not all plants need the same solution. Think about scale, SKU mix and capital.

Small or artisan producers

- Look for compact, semi-automatic or benchtop depositors with straightforward operation.

- Prioritize machines that are easy to clean and simple to maintain.

- Consider modular systems that allow expansion later.

Why: small producers need flexibility and low upfront cost; they value machines that fit in tight spaces and support many SKUs.

Growing mid-sized producers

- Seek modular systems with upgrade paths (add heads, conveyors, or simple automation).

- Emphasize recipe management and recipe transferability across shifts.

- Ensure spare parts and local service are available.

Why: growing shops need scalability and predictable operating costs.

High-volume industrial plants

- Prioritize heavy-duty, sanitary designs, full automation, and integration with MES and packaging.

- Service agreements, redundancy (spare heads or parallel lines) and remote monitoring become important.

Why: uptime and integration drive ROI at scale.

Practical validation steps during supplier selection

Never accept a demo using only the vendor's chocolate. Test with your own formula under realistic conditions.

Demo checklist

- Run a sustained deposit test using your actual formulation; record portion weights, standard deviation, and throughput.

- Time a full changeover including nozzle swap and clean-down using your cleaning protocol and personnel.

- Verify temperature stability across hopper and nozzle zones under production load.

- Test recipe recall and trace log export.

- Validate cleaning access: watch a full disassembly and reassembly if you plan manual cleaning.

- Confirm electrical, air and cooling requirements fit your site.

- Observe operator ergonomics: is access comfortable and is control intuitive?

Documentation to request

- Maintenance manuals and service schedules.

- Spare parts list with expected life metrics.

- Performance data from existing installations.

- Contactable references in similar production environments.

Real-world demos reveal issues invisible in spec sheets: nozzle clogging with inclusions, pump starvation when viscosity spikes, or a control sequence that confuses operators.

Integration, layout and commissioning best practices

A depositor must be viewed as part of a line. Plan utilities, line flow and commissioning before the machine arrives.

Utilities and footprint

Confirm electrical supply, compressed air quality and cooling circuits. Ensure floor loading and access for maintenance are adequate. Late changes to utilities cause costly delays.

Line layout and buffer zones

Design to prevent bottlenecks. Include buffer conveyors, tilt trays or smart accumulation if packaging runs at a different speed than depositing.

Commissioning phases

- Dry run: test movement, conveyors and interlocks without product.

- Water or syrup run: validate pump behavior and seals.

- Full product run: validate control points and sample the product for portion accuracy and appearance.

Include your operators in commissioning — they are the people who must run and maintain the line.

Cleaning, allergen control and hygiene considerations

Sanitation is vital. Poor cleaning practices lead to recalls, off-flavors and lost production.

Design for cleaning

Machines designed with CIP or tool-free disassembly reduce cleaning time. Where CIP isn't possible, the machine should allow quick access to contact surfaces and have minimal crevices.

Changeover and allergen management

Documented changeover procedures and swab testing standards reduce risk. Allow for post-clean validation runs where necessary.

Cleaning validation

Keep cleaning logs and test reports. Auditors value clear records and a tested cleaning regime.

Maintenance strategy and spare-parts planning

Uptime depends on planned maintenance and sensible spares.

Routine maintenance cadence

- Daily: visual checks, temperature checks, quick seal inspection.

- Weekly: pump seal inspection, nozzle wear check.

- Monthly: drive and motor checks, sensor calibration.

Quarterly or per runtime: liner and seal replacement, bearing checks.

Predictive approaches

Log trends: power draw, temperature drift and vibration. Small trends often predict issues before they force a stop.

Spare parts

Stock the parts that take the machine offline for long: seals, gaskets, a spare nozzle set, and critical sensors. Discuss lead times with the supplier and arrange accelerated shipping options for emergencies.

Customization, special requirements and prototyping

You may need custom heads, multi-shot deposition, or specialized conveyors. Custom work is common, but manage it carefully.

How to structure customization

- Define functional requirements and acceptance tests up front (portion weight tolerance, cleaning time, integration tests).

- Insist on pre-production prototypes and run validation with your ingredients.

- Document spare-parts supply for custom components and agree on ownership of design changes.

When to use integrators

Systems integrators can combine modules from different suppliers and manage control logic. This is useful when you want specific pumps or vision systems that a single vendor does not provide.

Cost considerations and how to calculate ROI

Don't compare machines by sticker price alone. Include operating, cleaning, spares and labor savings in the calculation.

ROI elements

- Labor saved per shift × wage.

- Giveaway reduction per unit × units per year.

- Fewer rejected packs or rework episodes.

- Faster product introduction and the revenue that brings.

- Maintenance hours reduced by faster cleaning or better reliability.

Ask suppliers for case studies and help calculating ROI using your production numbers.

Common pitfalls and how to avoid them

Avoid these frequent mistakes:

- Accepting vendor product for demos: always bring your own formulation.

- Ignoring cleaning time: a low-cost machine can cost more in cleaning labor.

- Failing to verify spare-part lead times: long waits equal lost production.

- Underestimating integration work: a machine that won't talk to your MES is a future expense.

Practical mitigation: use a checklist, require demos with your product, and get documentation on spares and service SLAs before signing.

A practical pre-purchase checklist

Use this checklist when comparing suppliers:

- Did you run your product in a demo?

- Are portion repeatability and throughput documented?

- Have you timed a real changeover and cleaning?

- Are spare parts and lead times acceptable?

- Does the HMI support recipe management and trace logging?

- Can the machine integrate with your line controls?

- Is local service or an authorized partner available?

- What is the total cost of ownership, not just purchase price?

- Are warranty and service terms clear and acceptable?

- Have you received at least two production references?

This simple list reduces surprises and helps select a supplier aligned with real production needs.

Matching capability to intent

The right depositor and the right manufacturer are not about getting the fanciest spec sheet. They are about matching capabilities to your product mix, throughput goals and cleaning regime. Small shops benefit from flexible, cleanable modules that grow with them. Large producers need robust, integrated systems with predictable uptime and a service network.

Pick a supplier who will test with your materials, has a clear spare-parts and service plan, and offers meaningful references. Plan for maintenance, validate cleaning, and document acceptance criteria before installation. Do those things and the depositor will be one of the reasons your line runs reliably and your products hit the consistent quality your customers expect.

English

English Español

Español