Introduction to Chocolate Coating Pans

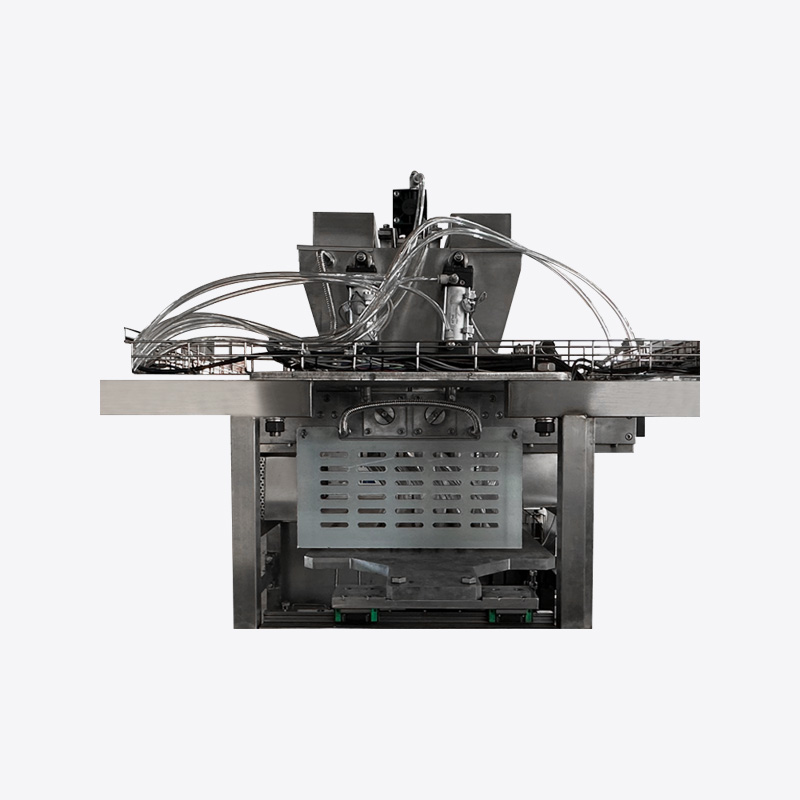

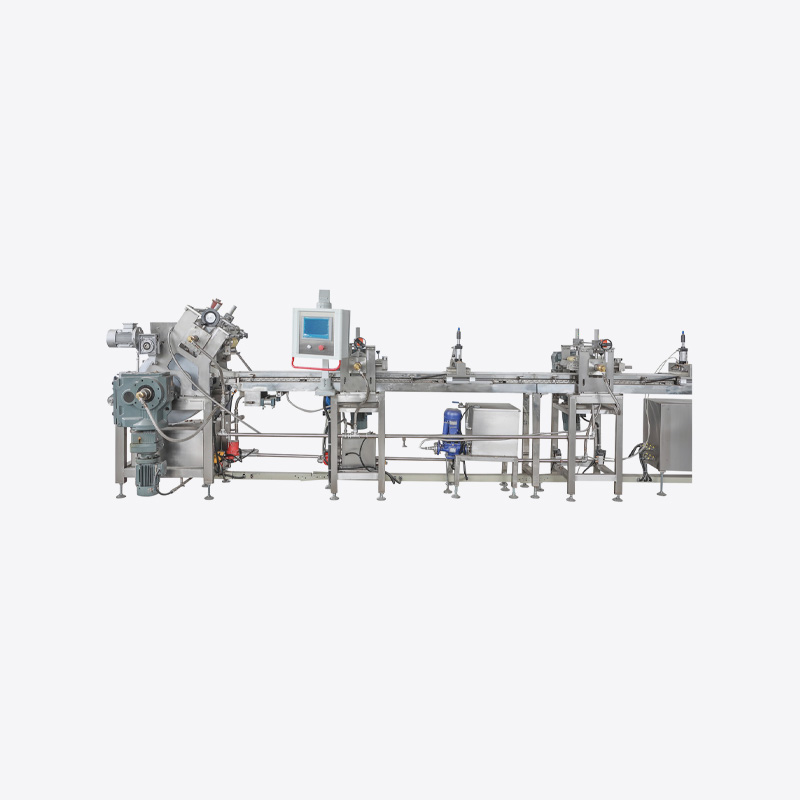

Chocolate coating pans are specialized equipment designed for enrobing, polishing, and coating confections with chocolate. Widely used in candy production, nut coating, and chocolate-covered snacks, these pans provide consistent coverage, smooth finishes, and improved visual appeal. The pan typically consists of a rotating drum, a heating system, and a controlled airflow mechanism that allows chocolate to be evenly applied to a variety of products.

A common question for chocolate producers is whether these pans are suitable for hot or cold chocolate. The answer depends on the pan’s design, heating capabilities, and the type of chocolate being used. Understanding these factors ensures the best coating results, prevents chocolate crystallization issues, and maintains product quality.

Types of Chocolate Used in Coating Pans

Chocolate coating pans can work with both hot (melted) and tempered chocolate as well as pre-cooled or cold chocolate coatings. Each type has specific properties that affect viscosity, adhesion, and final appearance.

Hot or Melted Chocolate

Hot chocolate is typically melted to a specific temperature, usually between 30°C and 50°C depending on the chocolate type. It flows easily, allowing for uniform coverage of confections. The pan’s rotating motion ensures that the chocolate adheres evenly, while the gentle heat prevents premature solidification. Hot chocolate is ideal for enrobing nuts, candies, and small confectionery items where a smooth, glossy coating is desired.

Cold or Tempered Chocolate

Cold or tempered chocolate is used when a thicker, more controlled coating is required. Pre-cooled chocolate allows for slower setting times, which is suitable for layered coatings or products that require multiple chocolate applications. Tempered chocolate also ensures a shiny finish and prevents fat bloom, maintaining the chocolate’s aesthetic and textural qualities.

Pan Design and Heating Capabilities

The suitability of a chocolate coating pan for hot or cold chocolate largely depends on its design and heating system. Industrial coating pans often include an integrated heater and temperature control, allowing operators to maintain chocolate at an optimal viscosity for coating. Air circulation systems can also help control cooling or heating during the coating process.

Smaller or manual coating pans may not have active heating, making them better suited for cold or tempered chocolate applications. For these pans, chocolate is melted externally and poured into the pan at the appropriate temperature, ensuring proper coating without overheating the product.

Factors Affecting Chocolate Coating

Several factors influence whether hot or cold chocolate is more suitable for a particular coating operation. These include the chocolate’s viscosity, product size, rotation speed, and ambient temperature.

Viscosity and Flow

Hot chocolate has lower viscosity and spreads more easily, which is ideal for thin, even layers. Cold chocolate, being thicker, is better for multiple coatings or when a textured surface is desired. Adjusting the chocolate temperature ensures it flows adequately to cover products without dripping excessively.

Product Size and Surface Area

Small products like nuts or candies benefit from hot chocolate coating due to rapid adhesion and smooth coverage. Larger confections may require cold chocolate or layered coatings to prevent melting of previous layers and achieve consistent thickness. The pan’s rotation and tilting can be adjusted to accommodate different product sizes.

Advantages of Using Hot Chocolate in Coating Pans

- Provides smooth, glossy finish on small and uniform products

- Faster coating process due to lower viscosity and quicker adhesion

- Reduces the risk of incomplete coverage or clumping

- Easy to adjust temperature for different chocolate types (dark, milk, white)

Advantages of Using Cold or Tempered Chocolate

- Ideal for multiple coating layers or thick chocolate shells

- Prevents premature melting of coated products during layering

- Helps maintain sharp details and textures on complex shapes

- Minimizes risk of fat bloom when properly tempered

Practical Tips for Optimal Coating

For the best results, chocolate coating pan operators should consider temperature, rotation speed, and product preparation. Ensuring chocolate is at the correct temperature before adding it to the pan prevents over-melting or hardening. Slow rotation helps distribute chocolate evenly, while proper airflow and ambient temperature control aid in setting.

In many modern industrial setups, operators use a combination of hot chocolate for initial coating and cold or tempered chocolate for finishing layers. This method balances speed, finish quality, and structural stability, producing consistent, high-quality products.

Comparison of Hot vs Cold Chocolate in Pans

| Chocolate Type | Best Use | Advantages | Considerations |

| Hot/Melted Chocolate | Rapid coating, small products | Smooth finish, fast adhesion | Must maintain temperature, avoid overheating |

| Cold/Tempered Chocolate | Layered coatings, thick shells | Prevents melting, maintains shine | Slower process, requires tempering knowledge |

Conclusion: Choosing Hot or Cold Chocolate

Chocolate coating pans are versatile tools suitable for both hot and cold chocolate, depending on the production goals and product requirements. Hot chocolate is ideal for fast, smooth coatings on small confections, while cold or tempered chocolate is better for layered applications and maintaining visual quality. Understanding the chocolate type, pan capabilities, and process parameters ensures optimal coating efficiency and consistent, high-quality results.

English

English Español

Español