The Future of Food Machines: Trends in Automation and AI

The world of food production has undergone significant transformations in recent years, and food machines have played a pivotal role in this evolution. From household kitchens to large-scale commercial operations, food machines are rapidly changing how we prepare, cook, and even consume food. As technology advances, the integration of automation and artificial intelligence (AI) is creating new possibilities that make food machines more efficient, precise, and even customizable. In this article, we will explore some of the most exciting trends in the future of food machines and how they will shape the food industry in the coming years.

Artificial Intelligence: Enhancing Food Machines with Smart Technology

One of the most impactful trends in the food machine industry is the increasing reliance on automation. Food machines have evolved from simple, manual devices to highly automated systems that can perform a variety of tasks with minimal human intervention. Automation in food production allows manufacturers to maintain consistency in product quality, reduce labor costs, and increase production efficiency.

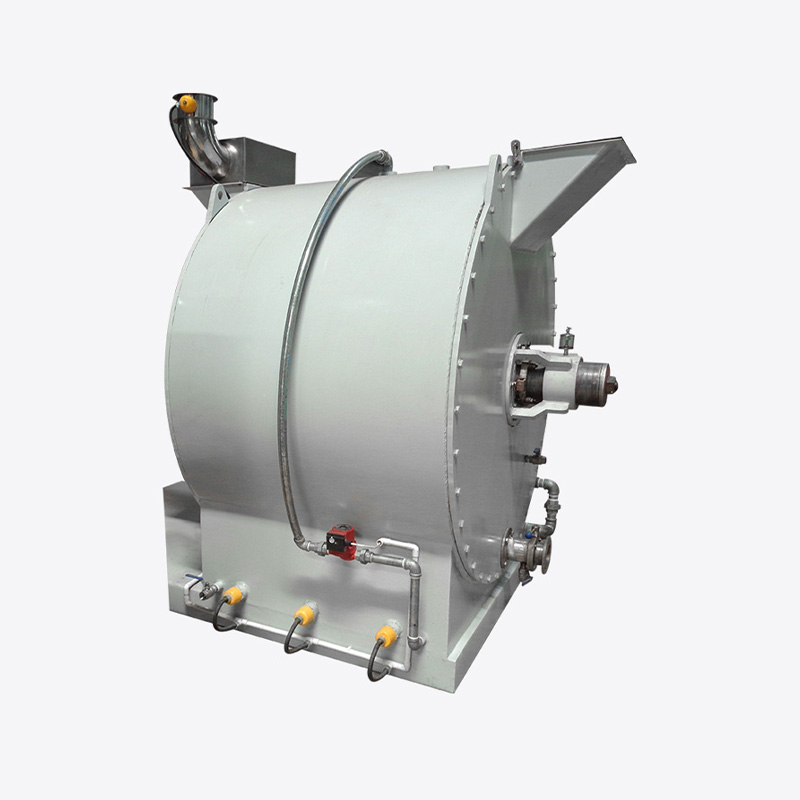

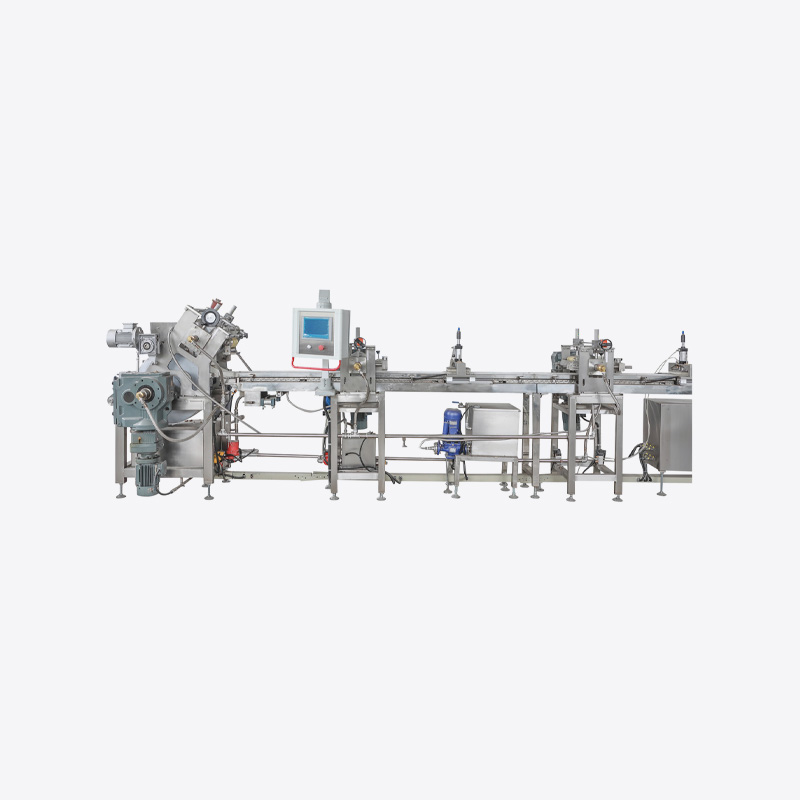

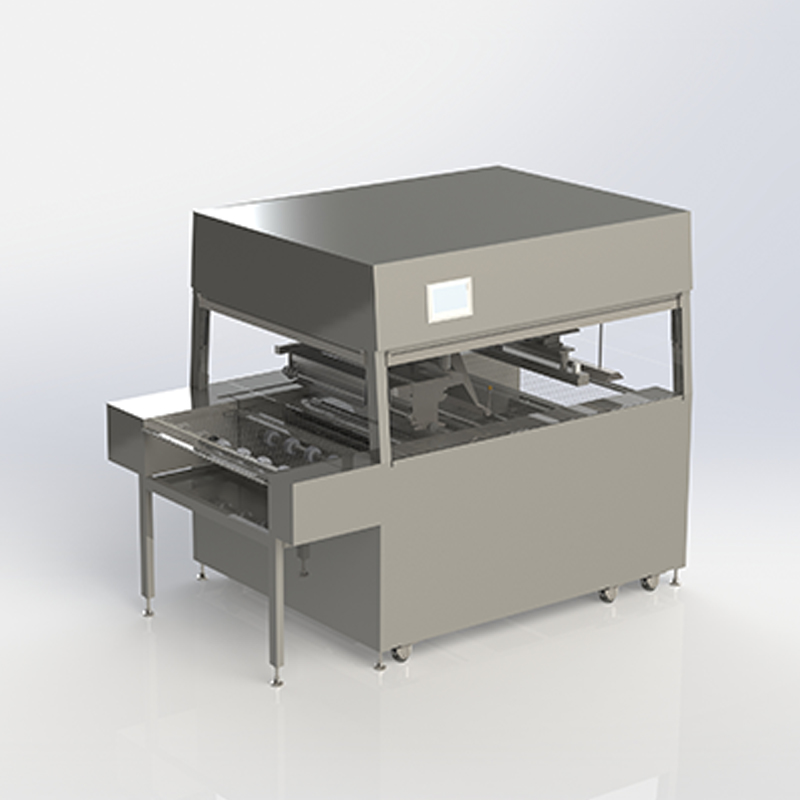

For example, in large-scale food processing plants, automated food machines can perform tasks such as sorting, mixing, baking, and packaging. These machines are equipped with sensors and advanced controls that ensure each product meets the required standards. Automated systems are particularly beneficial in processes that require precision, such as chocolate production or bakery product manufacturing, where the exact temperature, timing, and ingredients are crucial to achieving the desired outcome.

The introduction of robotic arms, conveyor belts, and automated sorting systems has revolutionized food manufacturing. These machines work seamlessly to increase throughput and minimize human error. Furthermore, automation reduces the risk of contamination and enhances hygiene standards, which is essential in the food industry where safety is a top priority.

Artificial Intelligence: Enhancing Food Machines with Smart Technology

As artificial intelligence continues to evolve, its integration into food machines is becoming more common. AI-powered food machines are capable of learning and adapting to different production environments, optimizing processes, and even predicting issues before they occur. For instance, AI algorithms can analyze data from food production lines and make real-time adjustments to parameters such as temperature, pressure, or cooking time. This ensures the production process is always optimized for efficiency and quality.

AI is also helping to improve food machines' ability to personalize food products. In consumer-facing applications, such as food vending machines or automated kiosks, AI can recommend or customize meals based on customer preferences, dietary needs, or even health considerations. These AI-driven machines can create personalized meal plans, adjust ingredients, and modify recipes to cater to individual tastes or requirements.

Moreover, AI-powered food machines can improve food safety by monitoring critical parameters and flagging potential risks. For instance, smart temperature sensors can ensure that food is stored at the right temperature, reducing the risk of spoilage or contamination. These smart systems can also predict maintenance needs, alerting operators when a machine requires servicing, thereby preventing downtime and reducing repair costs.

Sustainable Practices in Food Machines

Another key trend in the future of food machines is sustainability. With increasing concerns over the environmental impact of food production, manufacturers are looking for ways to design and implement more sustainable practices in food machinery. The food industry is increasingly adopting energy-efficient machines that consume less power and water. Moreover, many food machines are designed with the goal of reducing food waste by optimizing ingredient usage and minimizing production scraps.

For example, modern food machines are now able to precisely measure ingredients, reducing the risk of overuse or waste. Machines that produce food products like snacks, chocolate, or baked goods are being designed to maximize ingredient yield and minimize scrap production, which helps reduce both food waste and energy consumption.

Additionally, manufacturers are integrating recycling technologies into food machines, allowing food waste to be repurposed and reused in the production process. Some food machines are even designed with biodegradable or recyclable materials, further reducing their environmental footprint.

Customization and Consumer Demand

As consumers become more health-conscious and demand more personalized products, food machines are adapting to meet these needs. In the future, we will see an increased demand for food machines that can customize recipes, ingredients, and portion sizes based on individual preferences. Personalized nutrition is becoming a significant focus in food production, and food machines will play a crucial role in delivering tailored food options.

For example, machines in restaurants, cafes, and quick-service eateries may allow customers to customize their meals, from ingredient choices to cooking methods. AI-powered systems can suggest ingredient substitutions for customers with dietary restrictions, such as gluten-free or vegan options, ensuring a personalized dining experience.

Food machines will also enable on-demand food production, where consumers can select a recipe, and the machine prepares and delivers it in real-time. These machines will likely become more prevalent in homes and small-scale food businesses, allowing for quick, fresh, and customizable meals.

Embracing the Future of Food Machines

The future of food machines is exciting, with rapid advancements in automation, AI, sustainability, and customization. These trends are transforming food production at all levels, from home kitchens to large-scale industrial operations. By incorporating smart technologies, automation, and sustainable practices, food machines are not only improving efficiency and product quality but also helping meet the growing consumer demand for personalized and sustainable food options.

As the food industry continues to evolve, manufacturers and consumers alike must embrace these innovations to stay ahead in a competitive and fast-paced market. At Gusumachinery, we are committed to designing and producing cutting-edge food machines that align with the latest trends in automation and AI, ensuring that your production lines remain efficient and adaptable to future needs.

Whether you're looking to enhance your chocolate production process with precision or optimize other food manufacturing needs, Gusumachinery provides high-quality equipment designed to meet your specific requirements. For more information on our products, visit our Chocolate Chips Depositor page and discover how we can help your business thrive in the future of food technology.

English

English Español

Español