How Chocolate Enrober Improves Efficiency and Quality in Modern Factories

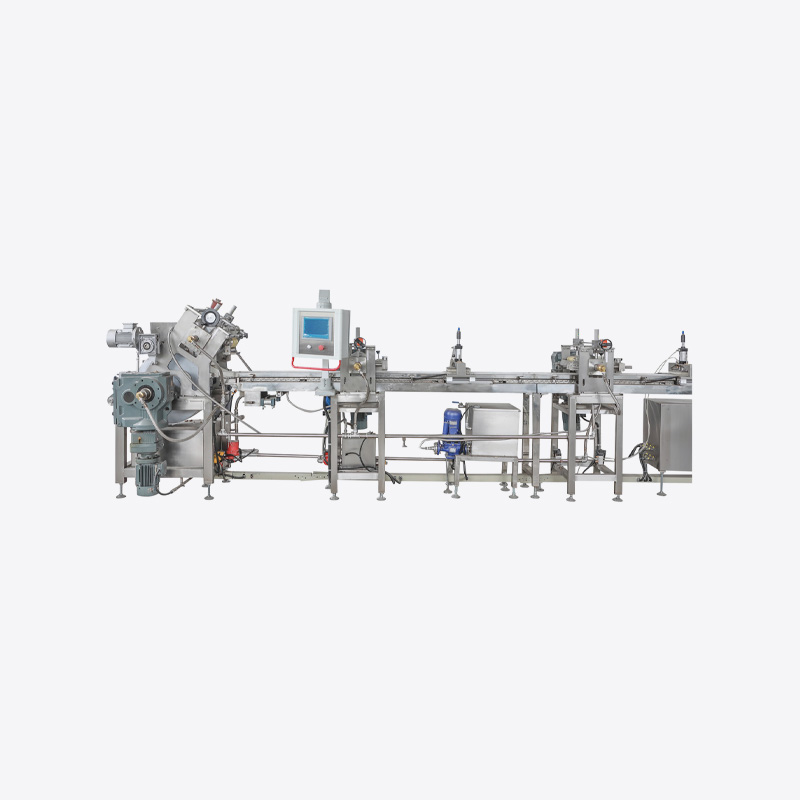

Chocolate Enrober equipment sits at the heart of many confectionery lines: it melts and conditions chocolate, delivers a controlled coat over a center, and helps move the item through cooling and packing with minimal manual touches. Get the enrobing stage right, and downstream tasks—packaging, storage, and display—are easier to manage. Miss the mark, and you can end up with uneven coatings, excessive waste, and extra shifts of rework that nobody budgets for.

Why an enrobing line matters more than its price tag

At first glance the enrober is a single machine on a long line. In practice it's a coordination point where chocolate rheology, mechanical timing, and thermal control meet. Thoughtful selection and operation affect four things that matter most to manufacturers:

- Product appearance — a consistent finish, clean edges, and an even gloss sell better and reduce customer complaints.

- Process reliability — predictable output removes surprise downtime and stabilizes labor planning.

- Material efficiency — the right dosing and removal tools cut chocolate waste and lower ingredient spend.

- Changeover speed — quick, repeatable swaps between SKUs keep small-batch and seasonal runs profitable.

When engineers and plant managers treat the enrober as a process node—not as a commodity purchase—improvements are measurable: less start-up scrap, fewer manual touchups, and a lower rate of finished-product defects that lead to rework.

What makes an enrober efficient for small factories

Small factories have different priorities than high-volume plants. Space, labor, and the ability to run multiple SKUs flexibly matter. An efficient enrober for small operations is not necessarily the most feature-dense machine on the market; it's the one that matches the factory's rhythm.

Key traits for small factories:

- Compact footprint with modular options. A compact base machine that supports modular add-ons—extra dosing heads, a short cooling section, or a small temperer—lets the line grow as demand rises without replacing the core unit.

- Fast, straightforward cleaning. If a machine takes a half-day to disassemble and clean, small teams will lose a production shift. Quick-release covers, sloping drain paths, and minimal dead zones speed hygiene work.

- Recipe memory for repeatability. Save and recall process recipes (temperature, pump speed, conveyor rate) to reduce operator variability between runs.

- Reasonable automation that reduces labor without requiring heavy operators. A few automation assists—stable dosing pumps, an adjustable air knife, and a gentle belt centerer—can cut hands-on time while keeping cost and complexity low.

A practical example: a boutique chocolatier that moved from manual enrobing to a compact automated enrober reduced their daily finishing time by nearly half and improved finish uniformity because the dosing and knock-off control removed operator inconsistencies.

How the enrobing stage improves coating consistency

Consistency is about repeatability. The consumer sees uniform appearance; the factory benefits from predictable weights and yields. Three technical elements dominate coating consistency:

Stable chocolate temper and reservoir control

Chocolate must be in the right crystalline form and at stable viscosity to coat evenly. Reservoirs with robust temperature control and good stirring prevent local overheating or cooling that produces streaks. A machine that holds narrow temperature bands across the reservoir and supply lines minimizes viscosity drift.

Smooth, pulse-free dosing

Steady pump output—whether gear, piston, or rotary pump—delivers a constant chocolate curtain or nozzle flow. Pumps that introduce pulsation show up as striping on the finished piece. For smaller runs, dosing valves with micro-adjustments can fine-tune film thickness without full hardware swaps.

Effective excess removal

Two products with identical chocolate flows will finish differently if the removal step is not tuned. Adjustable air knives, knock-off rollers, and vibrating decks help set the final film. The ability to vary removal intensity for different shapes and viscosities is vital.

These elements work together. For example, raising reservoir temp to increase flow without adjusting removal will lead to overcoating; raising flow and increasing air-knife pressure can restore the target film. Good process engineers document the relationship between the variables for each SKU.

Which features buyers should check in an enrober

When evaluating machines, checklist thinking beats feature-gloss. Here are practical features and why they matter.

Precision temperature control and homogeneity

Look for PID controls, separate zone heating, and active agitation. Ask for data on temperature stability during a long run.

Low-pulse pump technology and fine dosing control

Check pump type and ask whether the supplier can demonstrate continuous, pulseless flow at your intended viscosities.

Adjustable removal systems

Air knives with variable pressure and angle, and knock-off rollers with adjustable speed and gap, let you dial in final thickness. Accessories like vibrating tables smooth excess chocolate for certain textures.

Quick-change conveyors and modular tooling

If you switch between bars, pralines, or pieces with sticks, tooling that swaps in minutes saves time. Tooling plates and guides should be repeatable—one operator should restore settings in the same way each time.

Access for cleaning and Built-In CIP

Quick disassembly without tools, sloped drainage, and stainless surfaces reduce downtime. CIP capability is a plus where available and suits high hygiene standards.

Controls and recipe memory

A user interface that stores recipes and permissions (operator vs engineer) reduces mistakes and preserves proven settings.

Spare parts and local service

Availability of critical spares (seals, pumps, conveyor belts) and a responsive service network affect downtime risk. Ask for a spare-parts lead time and local support contacts.

Buyers will find it useful to ask for an on-site trial or a factory demo using their own chocolate formula. That practical verification is often the most reliable predictor of performance.

Why routine maintenance extends machine life and uptime

A routine that combines quick daily checks with planned preventive maintenance reduces surprise failures. Chocolate enrobing is a demanding mix of heat, fat, and mechanical motion; neglect shows up quickly.

Daily checks (before and after shift)

- Confirm set temperatures and reservoir level.

- Wipe critical surfaces and filter screens to keep chocolate from baking.

- Check belts, guides, and conveyors for residue and alignment.

Weekly tasks

- Inspect dosing valves and pump seals for wear.

- Verify air-knife nozzles and clean any deposits.

- Check cooling tunnel fans and belt tension.

Monthly or scheduled maintenance

- Replace wear parts (seals, gaskets).

- Calibrate temperature probes and flow meters.

- Drain, clean, and inspect tanks or do a CIP cycle.

Predictive practices

- Keep runtime logs for pumps and schedule service before expected wear life ends.

- Retain a small stock of critical spares onsite—pumps, belts, and power supplies are common culprits in downtime.

Training matters: operators who know why a setting controls a result are less likely to over-tweak parameters. Documented checklists and short SOPs for cleaning and changeover reduce shift-to-shift variability.

Tips for adjusting enrober settings for different products

Different centers—biscuit, wafer, nougat, fruit paste—demand different approaches. Below are actionable tuning tips.

For thin, even coatings (e.g., enrobed biscuits)

- Maintain slightly higher temperature but stable; reduce dosing to minimal uniform film thickness.

- Increase air-knife removal force and fine-tune angle to produce a thin film without streaks.

- Fast conveyor speed helps maintain throughput.

For thick shells or heavy coverage (e.g., enrobed truffles)

- Increase dosing; ensure pump can handle the higher flow without pulsing.

- Reduce air-knife pressure and consider knock-off roller adjustment for a cleaner edge.

- Slower conveyor speeds allow chocolate to level before cooling.

For glossy finish

- Tight temper control plus gentle, uniform cooling zones are critical. Avoid rapid thermal shocks in the tunnel.

- Minimize mechanical disturbance post-knife to keep a smooth surface.

When coating sticky fillings or multi-component centers

- Control incoming humidity and dust.

- Consider a pre-chill step; colder centers reduce chocolate absorption and improve finish.

Documenting these settings per SKU and training operators to follow recipes helps keep product quality consistent across shifts and days.

Where to position an enrober in a production line for best workflow

Line layout affects hygiene, ergonomics, and throughput. Positioning choices are practical: place the enrober where it minimizes handling and eliminates cross-contamination risk.

Key layout tips:

- Adjacent temperer and reservoir: minimize piping length and heat loss. Short runs reduce pump stress and stabilize flow.

- Upstream depositor: if deposits feed the enrober, position them so transfer between depositor and enrober is gentle—misalignment here creates waste.

- Immediate cooling tunnel: the coated product should enter a cooling zone promptly to set the coating before packaging.

- Cleaning access: design line spacing to allow easy removal of covers and access to tanks without disassembling neighboring machines.

- Packaging proximity: shortened transport from cooling to packing reduces risk of marking and handling damage.

A compact, linear sequence—tempering → enrober → cooling → packer—is ideal for many operations. But modular lines that allow bypassing the enrober for alternate processes add flexibility, especially for multiproduct plants.

A compact comparison table for quick model selection

| Feature / Operation | Small-Batch Enrober | Mid-Range Modular Enrober | High-Volume Continuous Enrober |

|---|---|---|---|

| Footprint | Small, space-efficient | Medium, modular add-ons | Large, multiple heads and long tunnel |

| Changeover time | Short (minutes) | Moderate (30–60 min) | Longer but with tooling carts |

| Dosing control | Manual fine tuning | PLC recipes, low pulse pumps | Precision servo pumps, multi-head dosing |

| Cleaning | Manual disassembly | Partial CIP options | Full CIP and automated drains |

| Throughput | Low–medium | Medium–high | Very high |

| Best for | Artisan & small brands | Growing factories | Large branded manufacturers |

Common production problems and clear troubleshooting steps

When finish or flow deviates from baseline, follow a structured approach—measure, change one variable, observe—so you find the true cause without creating new issues.

Problem: uneven coating (stripes, streaks)

- Check pump pulsation and reservoir agitation.

- Inspect nozzle or curtain for obstruction or wear.

- Verify temperature uniformity in reservoir and lines.

Problem: dull or mottled surface

- Confirm tempering curve and cooling tunnel profile.

- Look for contamination—residual fats from previous products can change surface behavior.

- Control humidity in the packaging and setting area.

Problem: too much scrap at start-up

- Use a warm-up purge routine to stabilize temperature and pump flow before releasing product.

- Keep small reclaimed trim segregation for rework where food safety standards allow.

Problem: operator variance between shifts

- Implement recipe locks with role permissions.

- Require shift handover logs and short training refreshers.

A short logbook at the machine where operators note parameter changes and observations becomes an invaluable tool over weeks and months.

How better enrober use reduces waste and cost

Waste reduction is a direct business benefit. Here's how effective enrobing cuts cost:

- Reduced start-up waste through pre-conditioning and purge management.

- Less over-coating via precise dosing and tuned removal controls.

- Lower rework rates by standardizing recipes and operator training.

- Trim recycling where permitted, controlled and tracked for food safety.

Consider the financial impact: a small reduction in average coat thickness across thousands of bars per week translates to significant ingredient savings over a quarter. Likewise, cutting a few percentage points from scrap rates nets a clear ROI on better process control.

Purchasing and commissioning checklist

Before you buy, confirm these items to ensure a smooth commissioning:

- Test run with your chocolate and product on the prospective machine.

- Detailed acceptance criteria, including weight tolerance, surface finish, and cycle rate.

- Spare parts list and local lead times for critical components.

- Training scope and documentation—operator guides, recipes, and maintenance schedules.

- Cleaning plan—how long a full clean takes and whether CIP is available.

During commissioning, perform an incremental ramp: test small runs, confirm results, then increase batch size. This protects both your schedule and the supplier relationship.

Operator training and process culture

Machines perform as well as the people who run and care for them. Invest in operator competence:

- Run short, focused training sessions on the relationships between temperature, dosing, and finish.

- Encourage recording and sharing observations. Small clues—like a slight odor or a minor noise—often foretell bigger issues.

- Reward consistency: celebrate when operators meet yield and finish targets.

A culture that values measured adjustments and documentation will naturally reduce variation and improve product consistency.

Match the machine to the process, not the spec sheet

A chocolate coating machine is not a point purchase: it's a process component. Selecting and operating it well means aligning features with product mix, training people to follow tested recipes, and backing operations with routine maintenance and spare parts. Prioritize practical performance—stable temperature control, pulseless dosing, and flexible removal—over an overloaded feature list.

English

English Español

Español