Chocolate Enrobers in Action: How They Shape the Chocolate Manufacturing Process

The chocolate industry is one of the most vibrant sectors of global food production, with consumers demanding ever more refined, high-quality products. Among the key technologies that contribute to this evolution is the chocolate enrober. A chocolate enrober is a pivotal machine in the production process, responsible for coating chocolates with a smooth, consistent layer of chocolate. This process not only enhances the flavor and texture of the final product but also ensures consistency and efficiency in production.

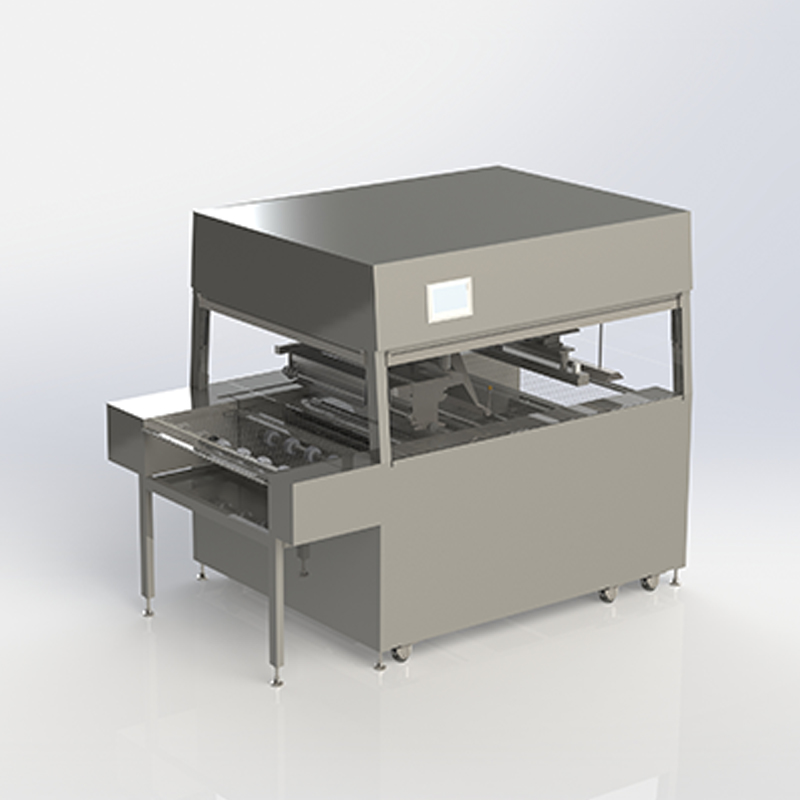

Gusu chocolate enrober is a piece of specialized machinery used in the final stages of chocolate production. It coats centers such as nuts, fruits, wafers, or creams with a layer of chocolate. This process typically involves a waterfall mechanism, where the central product moves through a stream of liquid chocolate that evenly coats it. The chocolate is then cooled and solidified in a controlled environment to ensure it maintains its smooth, glossy finish.

The enrobing process ensures that the coating is uniform, without bubbles or imperfections, which is critical for both the aesthetic and sensory qualities of the chocolate.

The enrobing process can be broken down into several key stages:

Preparation Stage: The chocolate is first melted and tempered to achieve the correct viscosity and texture for coating. Tempering ensures that the chocolate has the right crystalline structure, which affects its gloss, snap, and melting properties.

Enrobing Stage: The central product (such as a nut or fruit) is passed through the enrober, where it is evenly coated by a stream of liquid chocolate. This stage requires precise control to ensure an even coating is applied.

Cooling and Hardening: After the enrobing stage, the coated product is transferred through a cooling tunnel. The cooling process solidifies the chocolate coating, locking in its smooth texture and enhancing the firmness of the chocolate shell.

The chocolate enrobing process plays a vital role in enhancing the flavor profile of the final product.

Flavor Development: The chocolate coating helps to release the chocolate's natural flavors, which can be accentuated by proper enrobing conditions. A well-tempered chocolate with a smooth coating ensures the flavor is evenly distributed and intensifies during the consumption experience.

Temperature Control: The temperature at which the chocolate is enrobed directly impacts its flavor release. Too high a temperature can cause the chocolate to lose some of its delicate flavors, while lower temperatures help preserve its natural taste.

Coating Thickness and Flavor Balance: The thickness of the chocolate coating influences how much the center's flavor is balanced with the chocolate's flavor. A thinner coating allows the filling's taste to come through more, while a thicker coating creates a richer chocolate experience.

The texture and mouthfeel of chocolate are key factors that influence its consumer appeal. The enrobing process directly impacts both.

Smoothness and Gloss: The enrober applies a uniform layer of chocolate that gives the final product a smooth, glossy finish. This appearance not only appeals visually but also ensures a pleasant tactile experience when the chocolate is eaten.

Mouthfeel: The thickness of the coating affects how the chocolate feels in the mouth. A thin coating may provide a light, delicate experience, while a thicker coating offers a richer, more indulgent sensation. The snapping or crunching effect when breaking or biting into the chocolate is also influenced by the enrobing process.

Crunch and Snapping: Enrobing has a significant impact on the crunch factor, especially when the chocolate coating is thick. The speed at which the chocolate cools, combined with the coating's thickness, contributes to the texture's crispness.

One of the primary advantages of using a chocolate enrober is the efficiency it brings to the chocolate production process.

Automating the Process: Chocolate enrobing machines are designed for high-efficiency, automated operation. By reducing the need for manual labor, enrobers streamline the production process and increase throughput. This automation ensures that large volumes of chocolates can be produced quickly without compromising quality.

Consistency of Product Quality: Enrobing machines are designed to maintain consistent coating thickness and quality, ensuring that every piece of chocolate is uniformly coated. This consistency is crucial for meeting consumer expectations and maintaining product quality across production batches.

Cost Efficiency: By increasing production speed and minimizing waste, chocolate enrobing machines help reduce operational costs. This increased efficiency also helps manufacturers meet the growing demand for chocolate products without sacrificing quality.

Modern chocolate enrobing machines offer a high degree of customization to meet the diverse needs of chocolate manufacturers.

Customization for Different Products: Whether producing dark chocolate, milk chocolate, or even white chocolate, enrobers can be adjusted to suit different types of coatings and fillings. Additionally, the enrobing thickness can be tailored depending on the product type—thicker coatings for premium products, thinner ones for lighter confections.

Flexible Production: Chocolate enrobers can be adapted for a variety of fillings, from simple nuts to more complex fillings like nougat, caramel, or fruit. This versatility allows manufacturers to create a wide range of products using the same machinery.

In recent years, the chocolate enrobing industry has seen several technological advancements that have further optimized the process:

Latest Technological Advancements: Today's enrobers feature state-of-the-art temperature controls, which ensure the chocolate is applied at the perfect viscosity. Additionally, new designs allow for quicker cooling and more precise coating techniques, further improving quality.

Sustainability in Enrobing: With sustainability becoming a key focus in food production, manufacturers are increasingly looking for ways to reduce energy consumption in the enrobing process. Innovations such as energy-efficient cooling systems and optimized chocolate flow mechanisms help reduce environmental impact while maintaining production standards.

Chocolate enrobers are widely used by leading chocolate manufacturers globally. Some of the most successful brands leverage this technology to produce high-quality products at scale.

Case Studies: Many large-scale chocolate producers have integrated enrobing machines into their production lines to streamline operations and ensure the consistent quality of their products. This has allowed them to meet the ever-growing demand for chocolate while maintaining high standards of excellence.

Consumer Preferences: Consumers expect high-quality chocolate that not only tastes great but also has the right texture and appearance. Enrobing ensures that these expectations are met, creating a product that delights with every bite.

The chocolate enrober is an indispensable machine in the chocolate manufacturing process, shaping the flavor, texture, and overall quality of the final product. With its ability to automate production, ensure consistency, and improve both flavor and texture, the enrober plays a central role in the chocolate industry. By leveraging the capabilities of modern enrobing technology, manufacturers can deliver high-quality chocolates that meet the demands of consumers worldwide.

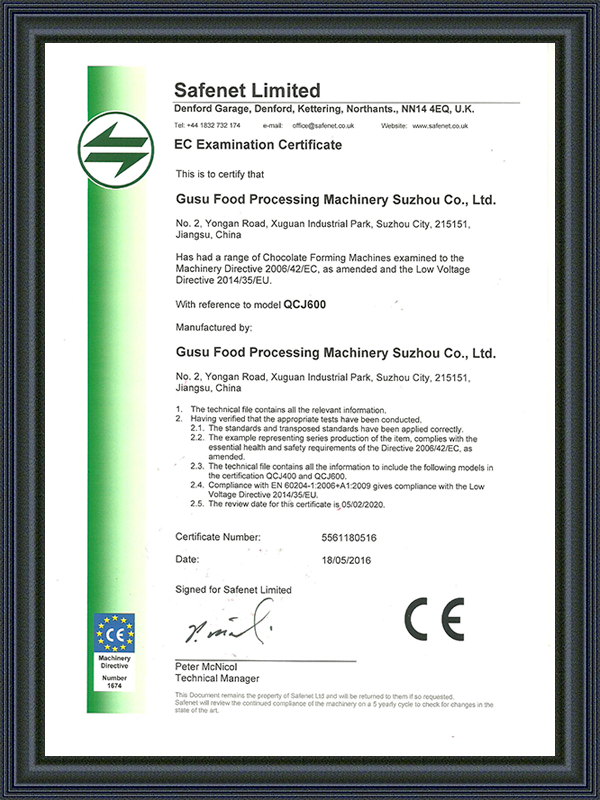

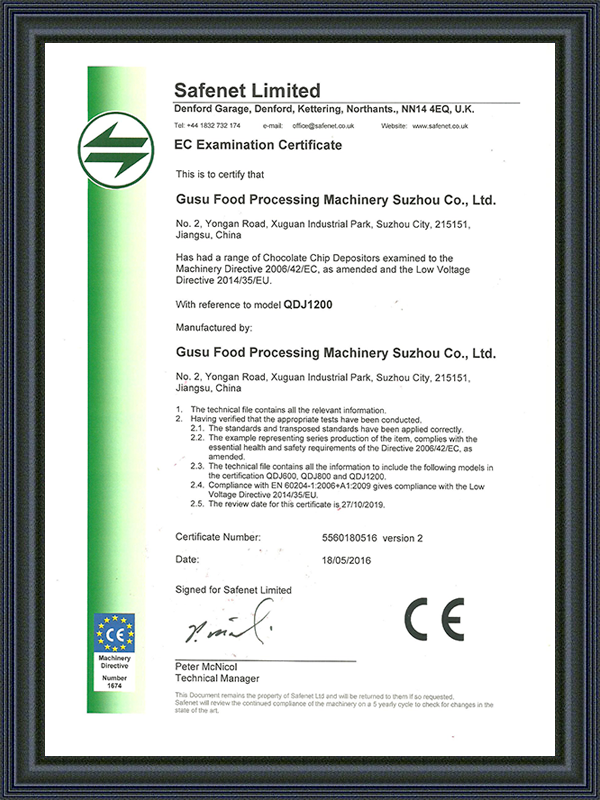

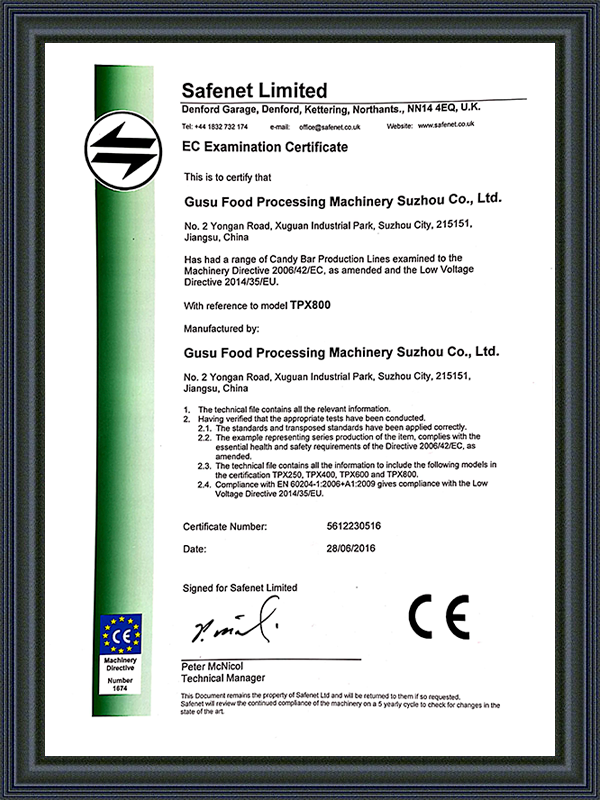

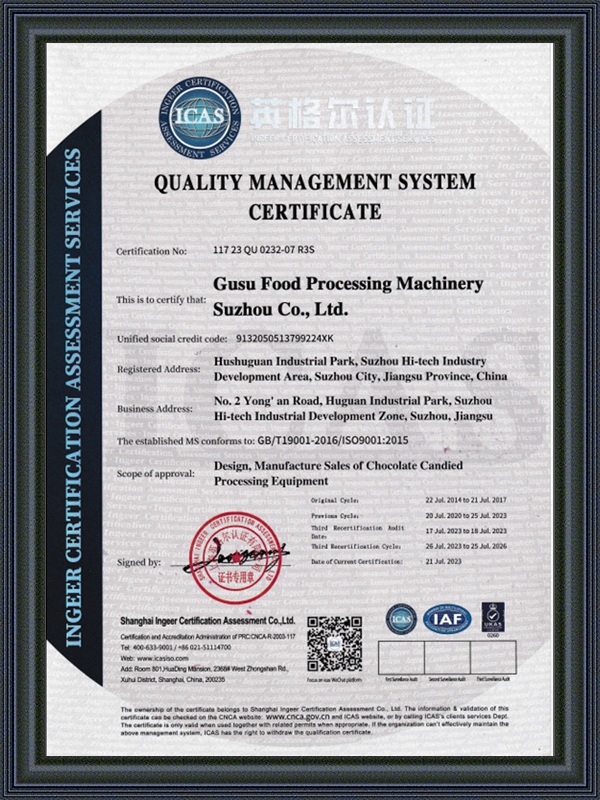

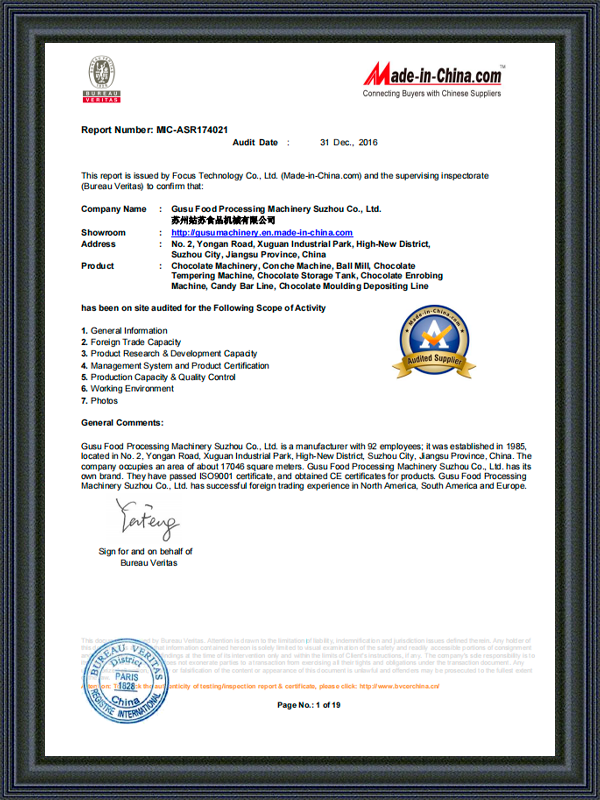

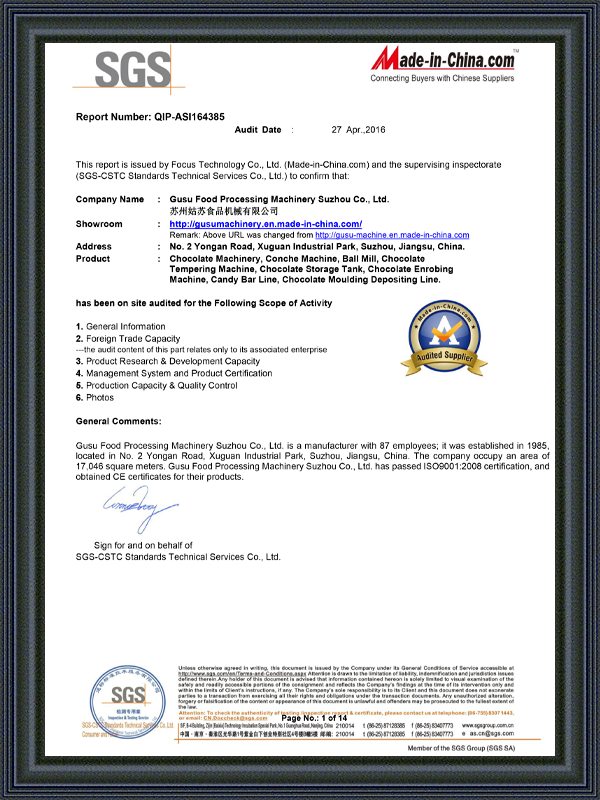

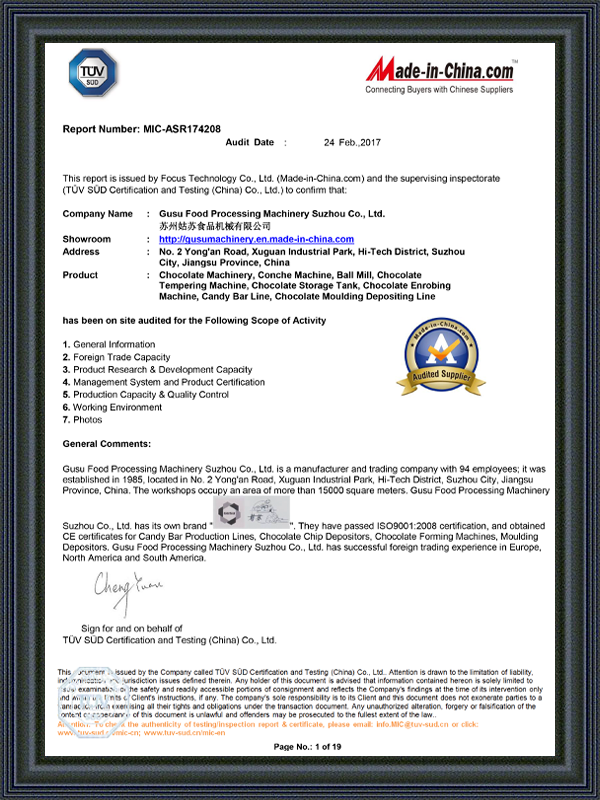

At Gusu Food Processing Machinery Suzhou Co., Ltd., we are committed to providing state-of-the-art chocolate enrobing machines that cater to the needs of chocolate producers. Our advanced technology ensures superior performance, efficiency, and product consistency, helping manufacturers optimize their processes and meet the growing demands of the chocolate industry. Whether you're producing premium chocolates or large-scale batches, our equipment is designed to deliver excellence in every piece.

English

English Español

Español